In the intricate world of structural engineering, understanding what a bridge bearing is can feel like deciphering an engineer’s version of alphabet soup, where phrases like “Rocker Bearings” sound more like a band than a crucial component. As unassuming as they might appear, these mechanical wonders are essential for transferring loads and accommodating movements in complex bridge systems. Bridge bearings serve not just to support structural integrity but also play an integral role in the longevity and safety of major infrastructure projects, such as highway bridges and municipal developments.

A bridge bearing is essentially a device that facilitates controlled movement and reduced stress on bridge components, tailored to absorb thermal expansion, vehicular loads, and dynamic forces. By effectively isolating structural deformations—and yes, occasionally translating them into forms even other engineers find challenging to pronounce—bridge bearings ensure that the delicate balance between stability and flexibility is maintained. Their selection process, influenced by bridge location, load specifications, and environmental factors, is as critical as the design of the bridge structure itself.

In this article, we delve into every critical aspect of bridge bearings—from types and selection criteria to their essential operational role in modern bridge design. We’ll examine the marvels of elastomeric and pot bearings, alongside others, each with its specific use cases and load capacities. Additionally, we explore how innovations and advancements in materials technology are shaping future possibilities for these unassuming, yet fundamentally important, pieces of engineering. Get ready to enhance your understanding and navigate the engineering nuances of bridge bearings with confidence.

What Are Bridge Bearings?

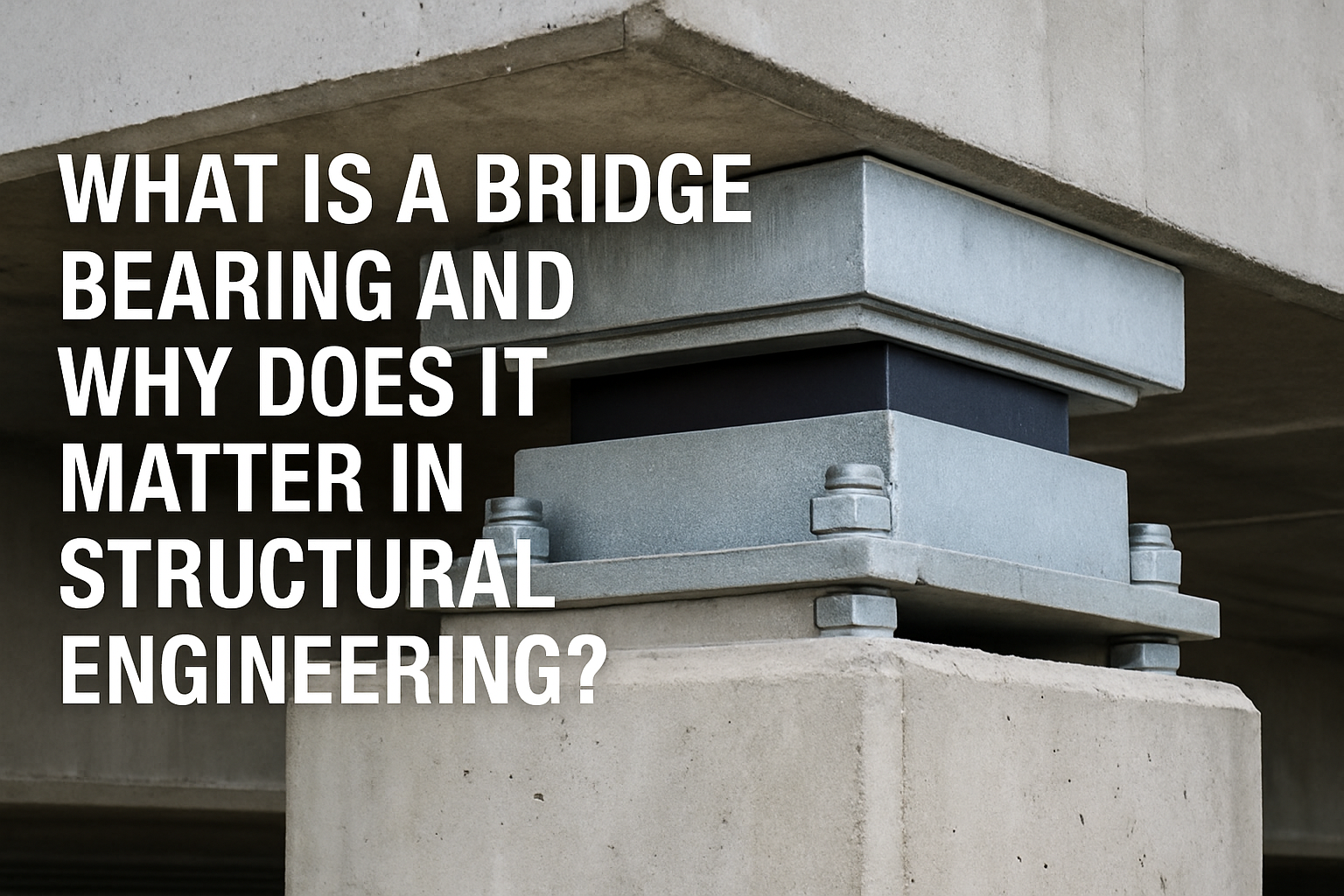

In the intricate world of civil engineering, answering the question “what is a bridge bearing?” reveals a component as essential as it is unassuming. Bridge bearings are vital devices positioned between the bridge superstructure and its supporting piers or abutments. They absorb movements and loads, mitigating the impact of thermal expansion, seismic activity, and daily vehicle loads. Without these crucial bearings, bridges would be at risk of significant structural stress, potentially leading to catastrophic failure.

Definition and Purpose

Bridge bearings serve a foundational purpose in modern infrastructure by facilitating controlled movement. These components enable bridges to respond flexibly to dynamic loads and environmental conditions, such as temperature fluctuations, all while maintaining structural integrity. By transferring loads from the deck to the piers efficiently, bearings help prevent undue tensile stresses. They also handle complex forces including horizontal deformations, allowing the bridge deck to ‘breathe’ even in horizontal directions. In essence, the role of bridge bearings is to permit both rotational and translational movements, ensuring safety and longevity.

Key Functions in Bridge Structures

A few key functions are crucial for ensuring the seamless operation of bridge bearings within structures. First, bearings accommodate movement caused by thermal expansion. Without this function, bridges could suffer from thermal-induced damages. Second, bridge bearings help to ensure vertical stiffness, counteracting the weight of vehicles and the bridge deck above. Finally, perhaps an unsung hero of seismic engineering, these bearings absorb vibrations and seismic loading, enhancing the bridge’s dynamic response and vibration attenuation performance.

In the grand theatre of infrastructure, bridge bearings may not be the stars, but they are indispensable members of the cast, safeguarding the structural performance and longevity of the bridges they support. To further explore solutions in custom fabrication for bridge infrastructure, explore trusted partners like Dews Foundry, whose technical expertise helps make projects a reality. Additionally, for further technical specifications and types of bridge bearings, consider reviewing resources such as those available from FHWA.

Types of Bridge Bearings

Understanding the types of bridge bearings is essential for civil engineers and infrastructure professionals tasked with ensuring the longevity and safety of bridge structures. Bridge bearings are crucial components that help manage the stresses and movements caused by dynamic forces such as traffic load, thermal expansion, and seismic activity. These bearings act as interfaces between the bridge deck and the bridge supports, facilitating controlled movements and reducing the loads transferred to the substructure. Different types of bearings are selected based on the specific needs of a project, including load capacity, movement type, and environmental conditions. Let’s delve into the primary types of bridge bearings.

Elastomeric Bearings

Elastomeric bearings are some of the most commonly used bridge bearings due to their flexibility and ability to accommodate rotations and shear movements. Comprised primarily of elastomeric materials like neoprene, these bearings can easily handle thermal expansion and minor seismic activity without the need for complex mechanical parts. Elastomeric bearings are often preferred for highway bridges where moderate to high tensile stresses can occur. Their design allows for significant horizontal deformations with low maintenance requirements, making them cost-effective solutions for many bridge projects.

Pot Bearings

Pot bearings are another robust option, specifically designed to support substantial loads and allow for rotational movements. They consist of a steel pot with a confined elastomeric disc, giving them the ability to accommodate large vertical loads with minimal horizontal movement. This design is particularly effective in heavy-duty applications where vertical stiffness is a priority. Pot bearings are often deployed in bridges where heavy vehicle loads are anticipated, providing a high degree of stability under dynamic forces.

Rocker Bearings

Rocker bearings are mechanical bridge bearings that enable rotational movement about a single axis, resembling the motion of a rocking chair—hence their name. These bearings are typically used in older bridge designs that demand reliable performance under moderate load conditions. They allow for horizontal directions of movement while maintaining vertical support. However, due to their mechanical complexity, regular maintenance is necessary to ensure their long-term performance. Rocker bearings handle vibration attenuation effectively, thus contributing to the bridge’s mechanical impedance and overall safety.

Guide Bearings

Guide bearings, also known as pinned bearings, are integral when precise directional movement control is required. They function by guiding the horizontal movements of the bridge while restricting the vertical and transverse movements, ensuring structural stability even under dynamic forces. This makes them suitable for use in seismic isolators or environments subject to seismic loading. Guide bearings excel in maintaining alignment within the bridge superstructure, making them indispensable in complex bridge projects where movement control is crucial.

Sliding Bearings

Sliding bearings are engineered to accommodate large horizontal movements and rotations through a combination of sliding surfaces. They usually consist of a PTFE (polytetrafluoroethylene) layer against steel plates, providing excellent wear resistance and low friction. These bearings are particularly effective in handling thermal expansion and contraction within bridges. Often used in conjunction with other bearing types, sliding bearings offer a practical solution for bridges subject to significant horizontal movement due to temperature fluctuations or seismic activity. They are key in ensuring the bridge’s adaptability to changing conditions while maintaining structural integrity.

Incorporating these bearings into infrastructure projects requires precise custom fabrication. For professional execution, partnering with trusted custom fabrication experts such as Dews Foundry guarantees components are designed and manufactured to meet specific project demands.

For a deeper dive into the technical specifications and performance requirements of bridge bearings, referencing resources from reputable sources, like AASHTO, can provide invaluable insights for engineering professionals.

Importance of Bridge Bearings

In the realm of civil engineering, understanding what a bridge bearing is can make the difference between a structure that gracefully ages and one that requires constant maintenance. Bridge bearings, often overshadowed by more attention-grabbing components like soaring arches or massive piers, play an unsung yet monumental role in ensuring the longevity and safety of bridge structures. These devices are strategically placed between the bridge superstructure and piers or abutments to accommodate a variety of forces and movements. With their diverse types and capabilities, bridge bearings facilitate thermal expansion, support vehicular loads, and control dynamic forces. Their design and selection are complex but pivotal, making them indispensable in modern infrastructure projects.

Facilitating Thermal Expansion

Thermal expansion is an inevitable phenomenon that engineers must consider during bridge design. As temperatures fluctuate, materials expand and contract, leading to stress and movement within the structure. Bridge bearings are meticulously placed to accommodate these movements, preventing any damage or stress that might otherwise compromise the bridge. By allowing the superstructure to move horizontally with the thermal changes, these bearings help maintain structural integrity. This functional flexibility is critical, particularly in regions with significant temperature variations, helping avoid undue stress and potential fractures in the material.

Supporting Vehicular Loads

The ability to bear vehicular loads is perhaps one of the most crucial functions of bridge bearings. These devices distribute the forces exerted by moving vehicles across the bridge deck, ensuring that loads are evenly transmitted to the underlying piers and abutments. Bearings must contend with fluctuating loads, considering both the daily commute and more extreme loads caused by oversized vehicles or emergency traffic. Their design focuses on providing the necessary vertical stiffness and capability to support varying weight demands through materials carefully selected for strength and resilience.

Controlling Dynamic Forces

Beyond static loads, bridge bearings are tasked with controlling dynamic forces, such as those induced by wind, seismic activity, or the vibrations of traffic. These forces demand bearings that can absorb, dissipate, or modulate energy, thereby stabilizing the bridge under unusual stresses. The sophisticated design of bearings, including features like mechanical impedance and vibration attenuation performance, ensures that bridges can withstand these dynamic pressures. In seismic zones, bearings might also integrate seismic isolators to further buffer against tremors. Addressing these dynamic forces isn’t merely about safety; it’s a testament to the engineering prowess thriving at the heart of infrastructure projects.

Understanding Bridge Bearing Articulation

Bridge bearings are often the unsung heroes of civil engineering, enabling the seamless transfer of loads from a bridge’s superstructure to its substructure. But what is a bridge bearing, and why is it so crucial? In the simplest terms, a bridge bearing is a device installed between the superstructure and substructure of a bridge. It accommodates movements such as thermal expansion and contraction, seismic activity, and vehicular loads, allowing for smooth articulation of the bridge itself. While it may sound complex — and it certainly is, as the acronym-laden terminology implies — understanding bridge bearings is essential for those of us navigating the intricate web of infrastructure engineering.

Design Considerations for Curved Bridges

Curved bridges present unique engineering challenges, and bridge bearings are pivotal to their design. The alignment and contour of curved bridges necessitate specialized bearing articulation, allowing the superstructure to adapt to the directional and torsional forces exerted on it. Choosing the right type of bearing becomes crucial here — elastomeric bearings, for example, are often favored for their flexibility and ability to accommodate significant rotational and translational movements.

Engineers must evaluate load capacities and vibration attenuation performance, considering mechanical impedance and the necessity to resist tensile stresses. Custom fabrication solutions are especially valuable for curved bridges, as off-the-shelf bearings often fail to meet the specific demands of such designs. Dews Foundry offers an exceptional partnership in providing custom fabrication services tailored to unique project needs, ensuring structural integrity and longevity.

Multi-Span Deck Configurations

The complexity doesn’t stop with curved bridges; multi-span deck configurations further emphasize the need for precise bridge bearing selection. Multi-span designs incorporate several deck sections, requiring bearings that can manage horizontal deformations and maintain vertical stiffness at various points. Bearings like pot, disc, or sliding variants are typically employed, each serving unique functions based on load capacity and movement flexibility.

Multi-span bridges must also counteract dynamic responses due to vehicle load and seismic loading. Different bearing types, such as mechanical bridge bearings and seismic isolators, offer various levels of energy dissipation and vibration control. The choice of bearing affects not only the construction phase but also the bridge’s long-term performance and maintenance needs.

To proficiently navigate the complexities of multi-span configurations, an understanding of the interaction between the bridge deck, piers, and bearings is indispensable. This knowledge ensures the resilience and safety of the structure over its lifecycle. Reliable guidance from experts and detailed parameters, like those available in civil engineering resources such as the Federal Highway Administration, are critical to making informed decisions.

For more information about custom fabrication options that can enhance your next infrastructure project, check out this resource on custom fabrication.

This article included an internal link to Dews Foundry and an encouraging note on their exceptional custom services, while also integrating a link to a credible external resource for further reading on bridge bearings.

Maintenance and Replacement of Bridge Bearings

Bridge bearings are pivotal components in maintaining the structural integrity and functioning of bridges. These small yet mighty devices facilitate controlled movement and flexibility between the bridge superstructure and its supports, accommodating loads and environmental changes such as thermal expansion and seismic activity. Regular maintenance and timely replacement of bridge bearings are vital to ensuring bridges can safely endure the diverse stresses they encounter throughout their lifespans. In this section, we’ll delve into the crucial practices of maintaining and replacing bridge bearings, from consistent inspections to recognizing signs of wear and applying best replacement practices.

Regular Inspection Protocols

Regular inspection of bridge bearings is paramount to preemptively identifying potential issues. This routine task should be part of a comprehensive maintenance strategy that guarantees the effective performance of the bridge’s structural components. Inspections often involve detailed visual evaluations, tactile examinations, and mechanical tests that assess the bearings’ condition against predetermined safety standards.

During inspections, specific attention is devoted to checking for misalignment, excessive movement, or deformation of the bearing pads and steel plates. Engineers should also evaluate any changes in the bridge’s dynamic response and mechanical impedance, considering potential impacts on the bridge’s overall stability and safety. Such thorough inspections help identify early warning signs of deterioration, allowing for timely intervention and repairs that can prevent more severe, costly damage in the future.

Common Signs of Wear and Damage

Recognizing common signs of wear and damage in bridge bearings is crucial to maintaining bridge safety and longevity. Without timely detection, these seemingly minor issues can escalate quickly, undermining the structural integrity of the bridge with potentially dire consequences.

Early signs of wear often include visible cracks on bearing surfaces, unusual noise during bridge operation, or any irregularities in horizontal deformations. Engineers should also look out for shifts in the bridge’s vertical stiffness, as excessive deflection or tensile stresses could indicate worn-out elastomeric materials or neoprene bearing pads. Such anomalies often result from long-term exposure to vibration, vehicle loads, or environmental stressors, which challenge even the most robust designs.

Failing to address these symptoms promptly can lead to accelerated bearing degradation, increasing the risk of issues such as bearing pad misalignments, compromised load capacity, or even complete bearing failure. Such outcomes can significantly compromise a bridge’s structural health, emphasizing the importance of keen observation and regular, methodical inspections.

Best Practices for Replacement

Replacing bridge bearings is no trivial task; it demands precision and a profound understanding of engineering principles. Employing best practices ensures not only the longevity of the newly installed components but also enhances the overall safety and reliability of the bridge structure. Before carrying out a replacement, engineers need to carefully assess the specific bearing type and load requirements suitable for the bridge’s location, whether it involves dealing with extensive thermal expansion or significant vehicle load.

A systematic approach should be adopted when planning the replacement process. This typically includes detailed modeling and planning to simulate potential scenarios and pinpoint optimal solutions. Utilizing high-quality materials, such as elastomeric bearings with fiber reinforcement, can increase the durability and performance under various conditions, including seismic loading.

Moreover, partnering with experienced custom fabrication experts, like Dews Foundry, ensures that the replacement bearings meet stringent design specifications tailored to specific project needs. By prioritizing precision in design and installation, these best practices contribute to achieving efficient, safe, and sustainable bridge operations over time.

For more detailed information about bridge bearing types and specifications, a valuable resource is the Federal Highway Administration’s bridge bearing guidelines.

Innovations in Bridge Bearing Technology

In the ever-evolving world of civil and structural engineering, bridge-bearing technology continues to march forward, paving its way through uncharted territories. While bridge components may not get the limelight like bridges or arcs, the workhorses called bridge bearings are vital to ensuring the longevity and integrity of these megastructures. Recent innovations are redefining how we approach bearing design, offering improvements in load distribution, seismic response, and overall durability. This article delves into two key areas that are transforming this technology landscape: the use of metamaterials and advancements in additive manufacturing.

Use of Metamaterials

Metamaterials, artificial materials engineered to have properties not found in naturally occurring materials, are making waves in the field of bridge bearings. With their unique capabilities to control wave propagation and vibration, they offer promising advancements for structural applications. These properties are particularly significant in regions prone to seismic activity, where the bearings must absorb and dissipate energy effectively.

The innovative use of metamaterials enables the creation of bearings that can improve vibration attenuation performance and mechanical impedance. By doing so, they mitigate the dynamic responses that such structures encounter daily, especially for highway bridges with heavy vehicle loadings. As engineers grapple with the acronyms and complex formulas encapsulated in advanced structural design, metamaterials present a forward-thinking option that ironically steps outside traditional boundaries—just like trying to decode said formulas!

Moreover, these materials facilitate more efficient handling of the horizontal deformations and vertical stiffness requirements that systems encounter. This capability not only extends the longevity of the bearings but also contributes to the overall safety of the bridge superstructure. As with any superhero, it’s essential to weigh the kryptonite: cost and scalability challenges. But as research continues, metamaterials are becoming a plausible and less fantastical choice for future infrastructure needs.

Advancements in Additive Manufacturing

If metamaterials tiptoe into material science’s realm, then advancements in additive manufacturing boldy kick open the door to futuristic possibilities. Commonly known as 3D printing, additive manufacturing brings a new dimension to bridge-bearing technology by allowing precision custom fabrications that perfectly meet specific project requirements. This approach is invaluable when engineers want to optimize bearings within the constraints of municipal or large-scale projects without compromising on performance.

One of the primary benefits of additive manufacturing is the ability to create complex, bespoke components tailored to complex load-bearing requirements. This precision is pivotal in tailoring elastomeric or mechanical bridge bearings, such as sliding bearings or neoprene bearing pads, that might need quick adjustments to adapt to site-specific conditions. The customization process enables engineers to innovate several bearing designs previously deemed impossible through traditional manufacturing.

Furthermore, additive manufacturing reduces material wastage significantly—a boon for projects with environmental and budgetary restrictions. This efficiency pairs well with sustainability goals, which are increasingly becoming a major consideration for construction projects worldwide. By minimizing waste and enhancing precision, additive manufacturing elevates the standard at which new infrastructure is conceived and constructed. Though not entirely free from challenges like material strength guarantees, the technology continues to develop at an impressive pace, offering exciting prospects for future engineering endeavors.

For those in search of a dependable partner in bridge construction, Dews Foundry offers custom fabrication solutions tailored to meet the nuanced demands of modern infrastructure (https://dewsfoundry.com/steel-fabrication/). To comprehensively understand the nuances of bridge bearings, including current types and specifications, you might want to consult credible resources such as the Federal Highway Administration’s guidelines on bridge bearings (https://www.fhwa.dot.gov).

Challenges in Bridge Bearing Design

Designing bridge bearings is a pivotal aspect of civil and structural engineering, often overlooked for its complexity until you’re knee-deep in specifications and calculations. Bridge bearings are crucial components that support bridge superstructures, allowing controlled movements due to thermal expansion, seismic activity, and vehicle load variations. However, designing these bearings is rife with challenges that demand precision, innovation, and resilience. These challenges stem from environmental conditions, structural constraints, and the need for prolonged durability. Or perhaps it’s just another day at the office wrestling with a seemingly infinite acronym soup and their equally perplexing engineering squabbles.

Environmental and Structural Factors

The influence of environmental and structural factors on bridge bearing design cannot be understated. Varying temperature ranges lead to thermal expansion and contraction, while seismic activities necessitate bearings with excellent vibration attenuation performance and mechanical impedance. By controlling horizontal deformations, bearings directly impact a bridge’s stability. They must also bear tensile stresses, ensuring that they do not buckle under pressure during seismic loading. Moreover, environmental factors such as exposure to moisture and corrosive agents challenge material integrity. Thus, selecting appropriate elastomeric materials or opting for other bearing types like neoprene bearing pads becomes a decision of paramount importance. Understanding these factors is vital for selecting the right bearing that aligns with the specific requirements of large-scale infrastructure projects.

Case Studies of Engineering Solutions

Real-world engineering solutions offer valuable insights into overcoming challenges in bridge bearing design. For instance, a municipal bridge project in a seismic-prone area may demonstrate the use of mechanical bridge bearings and seismic isolators to mitigate earthquake impacts. Engineers often opt for spherical bearings for their excellent dynamic response and ability to manage horizontal directions effectively. Another highway project might highlight how sliding bearings accommodate displacements, ensuring safe load transfer from the bridge deck to piers. Each case study showcases how strategic bearing selection, rigorous testing, and innovative material use help meet specific design criteria. Such examples underscore the importance of comprehensive planning and collaboration with trusted partners like Dews Foundry for custom fabrication, ensuring the project meets both technical specifications and longevity requirements. This knowledge empowers decision-makers and engineers alike to tailor bearing solutions for diverse infrastructure challenges.

For detailed technical insights on bridge bearings and specifications, consider visiting resources like the Federal Highway Administration’s (FHWA) guidelines on bridge engineering methods here.

The Future of Bridge Bearings

As the backbone of modern infrastructure, bridge bearings are pivotal in supporting the dynamic load and integrity of structural systems. These crucial components bridge the gap between the bridge deck and its supports, absorbing movements and forces that might otherwise destabilize the structure. Their role, however, isn’t static; advances in material science and engineering are paving the way for the future of bridge bearings, ensuring they can meet the new challenges posed by modern infrastructure demands.

Emerging Trends and Technologies

Emerging trends in bridge bearings signal a shift towards more resilient and adaptable designs. The incorporation of advanced materials, such as elastomeric composites, enhances durability and resistance to environmental stresses. These innovative materials provide superior vibration attenuation performance, essential for maintaining structural integrity under dynamic loading conditions.

Moreover, the integration of smart sensor technologies in bearing systems allows for real-time monitoring of load and displacement, proactively addressing maintenance needs. Additive manufacturing, or 3-D printing, is another groundbreaking trend that enables custom fabrication of complex bearing shapes, enhancing load capacity and fitting precision, thus optimizing performance and lifecycle costs. Such advancements are not just buzzwords; they are tangible improvements engineered to increase safety margins and economic efficiency of municipal and highway bridges.

Implications for Structural Engineering

The implications of these trends for structural engineering are far-reaching, redefining how engineers design and maintain bridges. Enhanced monitoring capabilities enable predictive maintenance, reducing downtime and unforeseen failures. This shift from reactive to proactive management can lead to significant cost savings.

Furthermore, the utilization of new materials and fabrication techniques allows for greater flexibility in design and execution, enabling engineers to tackle complex projects with more confidence and precision. The improved performance of these bearings under seismic loading conditions and their ability to accommodate larger deformations without compromising safety expands the horizons of what’s structurally feasible, promising a future of bridges that are not only robust but intelligent.

For more detailed insights into bridge bearing specifications and performance requirements, the Federal Highway Administration (FHWA) offers comprehensive resources. Additionally, Dews Foundry stands as a trusted partner in custom fabrication, offering robust solutions for your infrastructure projects here.

This exciting evolution in bridge bearing technology promises to deliver next-generation solutions that meet increasingly sophisticated structural demands. By staying ahead of these trends, civil engineers and structural professionals can ensure their projects meet the highest standards of safety, efficiency, and innovation.

Frequently Asked Questions

A bridge bearing is a structural device positioned between a bridge's superstructure and its supporting piers or abutments. It facilitates controlled movement and load transfer, accommodating thermal expansion, vehicular loads, and seismic activity while maintaining structural integrity. Bridge bearings enable both rotational and translational movements, ensuring the bridge can respond flexibly to dynamic forces without compromising safety or longevity.

The main types of bridge bearings include elastomeric bearings (made from materials like neoprene for flexibility), pot bearings (designed for substantial loads with confined elastomeric discs), rocker bearings (mechanical bearings allowing rotational movement), guide bearings (providing precise directional movement control), and sliding bearings (using PTFE surfaces for large horizontal movements). Each type is selected based on specific load capacity, movement requirements, and environmental conditions.

Bridge bearings are crucial for safety because they prevent catastrophic structural failure by managing stress and movement. They facilitate thermal expansion, support vehicular loads by distributing forces evenly, and control dynamic forces from wind, seismic activity, and traffic vibrations. Without proper bearings, bridges would experience undue tensile stresses, potentially leading to structural damage or collapse. They also provide vibration attenuation and mechanical impedance, enhancing overall bridge stability.

Bridge bearings accommodate thermal expansion by allowing controlled horizontal movement as temperatures cause materials to expand and contract. They permit the bridge superstructure to move horizontally with thermal changes while maintaining vertical support, preventing stress buildup that could damage the structure. This functionality is especially critical in regions with significant temperature variations, where the bearings enable the bridge deck to "breathe" and adjust naturally to thermal conditions.

Common signs include visible cracks on bearing surfaces, unusual noise during bridge operation, irregularities in horizontal deformations, excessive deflection, compromised vertical stiffness, and bearing pad misalignments. Other indicators are changes in the bridge's dynamic response, increased tensile stresses, and deterioration of elastomeric materials or neoprene bearing pads. Early detection through regular inspections is crucial to prevent accelerated degradation and potential bearing failure that could compromise bridge structural health.

Key innovations include metamaterials that provide superior vibration attenuation and mechanical impedance control, additive manufacturing (3D printing) enabling custom fabrication of complex bearing designs, smart sensor technologies for real-time monitoring of load and displacement, and advanced elastomeric composites offering enhanced durability. These technologies enable predictive maintenance, improved seismic performance, better load capacity optimization, and more precise custom solutions for specific infrastructure requirements.