Introduction: The Unseen Foundation of Modern Progress

From the sweeping arches of continent-spanning bridges to the sky-piercing skeletons of modern skyscrapers, our world is defined by feats of engineering that push the boundaries of what is possible. These monumental structures, however, rely on an often-unseen foundation: the meticulous, exacting process of steel fabrication. While the raw strength of steel is undeniable, it is the precision with which it is cut, shaped, and joined that transforms it from a simple material into the backbone of modern infrastructure.

The Backbone of Modern Society

Modern infrastructure—the complex web of transportation networks, energy grids, and urban centers—is fundamentally built on steel. Steel components provide the essential support and structural integrity that allow these systems to function safely and reliably. From the heavy steel plates forming the hull of a ship to the intricate latticework of a transmission tower, fabricated steel is the common denominator of progress. This essential role in nearly every facet of modern construction underscores its importance.

Defining Precision Steel Fabrication

Precision steel fabrication is a highly specialized discipline within the broader field of metal fabrication. It transcends simple cutting and welding; it is the science of transforming raw steel into structural components that adhere to minuscule tolerances, often measured in fractions of a millimeter. This process ensures that every beam, plate, and connection fits and performs exactly as specified by engineers. The market reflects this growing necessity, with the Precision Steel Fabrication Market projected to grow to USD 71.19 billion by 2034, highlighting its expanding role in global development.

The Article’s Thesis: Indispensable for Modern Infrastructure

The central argument is clear: precision steel fabrication is not merely a beneficial practice but an indispensable requirement for building safe, resilient, and efficient modern infrastructure. It is the critical link between architectural vision and structural reality, ensuring that the complex systems we depend on can withstand the immense pressures of the modern world. Without this commitment to precision, the integrity of our most vital structures would be compromised.

The Evolving Demands of Modern Infrastructure

The infrastructure of the 21st century is vastly different from that of previous generations. The demands placed upon these structures have grown in scale, complexity, and performance, necessitating an evolution in how we build them.

Scale, Complexity, and Interconnectedness

Today’s projects are larger and more intricate than ever before. We are building taller skyscrapers, longer bridges, and more expansive energy facilities. These structures are not isolated but are part of interconnected systems where the failure of one component can have cascading effects. This complexity requires every element to be manufactured with unparalleled accuracy to ensure seamless integration and collective stability.

Critical Performance Requirements

Modern infrastructure must perform under extreme conditions. Bridges must resist high winds and seismic activity, energy facilities must operate in harsh environments, and skyscrapers must safely support thousands of occupants. These performance requirements translate into stringent engineering specifications for every structural component. The fabrication process must meet these demands without fail, as the margin for error is virtually nonexistent.

Bridging Design Vision with Real-World Execution

Architects and engineers are continually pushing creative and functional limits with their designs. These ambitious visions often involve complex geometries, unique load-bearing requirements, and innovative material use. Precision steel fabrication is the essential process that translates these digital blueprints into tangible, high-performance structural components. It ensures that the elegant curve of a stadium roof or the slender profile of a supertall tower is not only aesthetically pleasing but also structurally sound.

Why Precision is the Cornerstone: Ensuring Structural Integrity and Performance

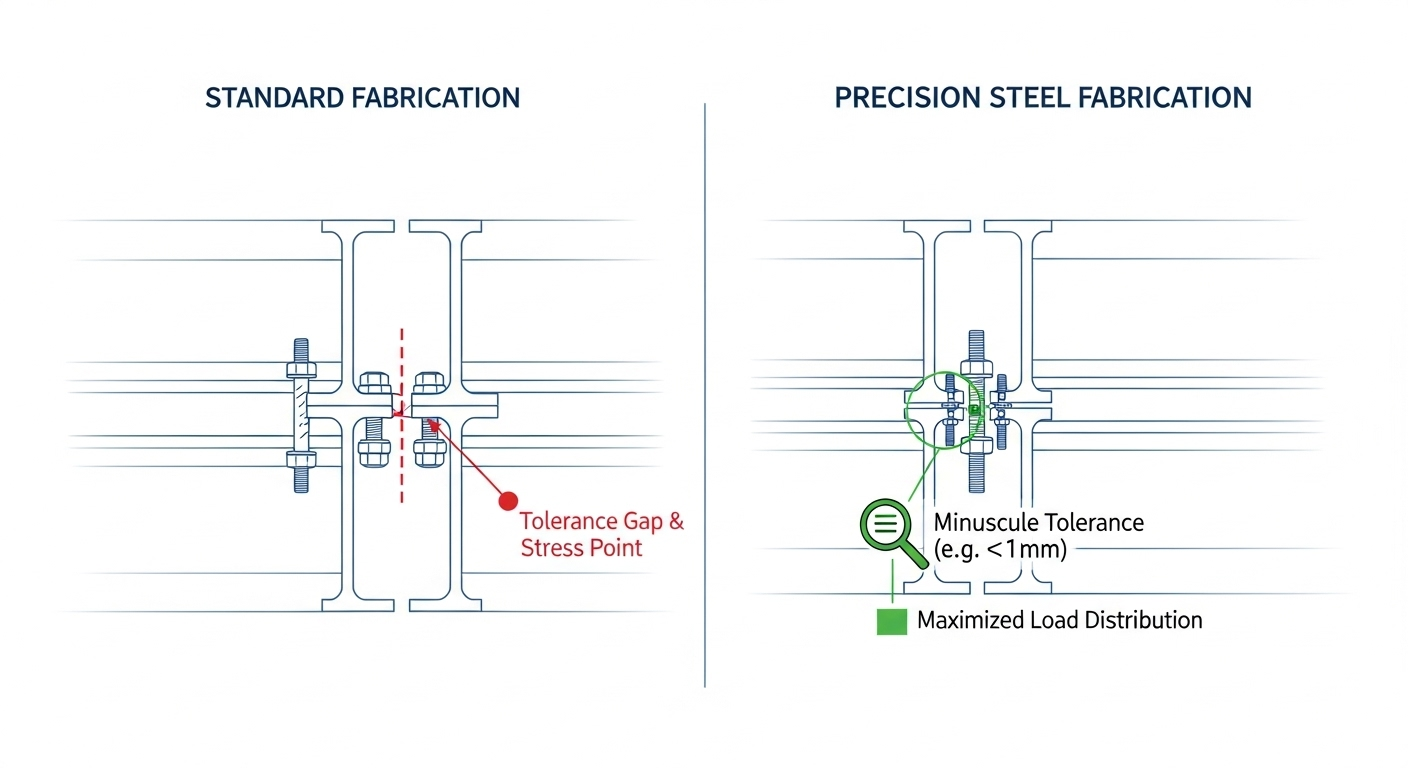

At its core, the obsession with precision in steel fabrication is about guaranteeing structural integrity. This foundation of safety and reliability is built on three pillars: maintaining integrity, adhering to strict tolerances, and delivering long-term performance.

The Foundation of Structural Integrity

Structural integrity is the ability of a structure to withstand its intended loads without failing. In steel construction, this begins at the fabrication stage. Precise cutting ensures that loads are distributed exactly as engineers intended, preventing stress concentrations that can lead to catastrophic failure. Accurate assembly and high-quality welding create joints that are as strong as the parent metal, forming a monolithic structure capable of bearing immense forces. Any deviation compromises this fundamental principle, turning a calculated design into a dangerous liability.

Durability and Longevity in Action

Infrastructure is a long-term investment. Bridges, power plants, and public buildings are expected to last for decades, often with minimal maintenance. Precision fabrication contributes directly to this longevity. When steel components fit together perfectly, they are less susceptible to premature wear, corrosion at misaligned joints, and fatigue from improper load distribution. This meticulous attention to detail during manufacturing translates into decades of reliable service, protecting both public safety and taxpayer investment.

Operational Efficiency and Reliability

The impact of precision extends beyond initial construction. In industrial and energy infrastructure, precisely fabricated components are critical for operational reliability. A slight misalignment in a turbine support structure or a pipeline flange can lead to vibrations, leaks, and costly downtime. By ensuring every component meets exact specifications, precision fabrication minimizes operational risks and enhances the overall efficiency of the facility. This is echoed in maintenance, where companies integrating IoT sensors for monitoring—often mounted on precisely fabricated supports—have reported a 30% decrease in maintenance expenses.

Advanced Technologies Driving Precision in Steel Fabrication

Achieving the required level of precision is not left to chance. It is the result of a synergistic relationship between human expertise and advanced technology, a process that ensures accuracy from the digital model to the finished product.

From Concept to Digital Blueprint

The journey to precision begins long before steel is cut. Engineers and architects use Building Information Modeling (BIM) and Computer-Aided Design (CAD) software to create highly detailed 3D models. These digital blueprints define the exact dimensions, connections, and tolerances for every structural component, serving as the single source of truth for the entire fabrication process.

State-of-the-Art Cutting and Shaping

These digital designs are fed directly into computer numerical control (CNC) machines. Technologies like high-definition plasma cutters, laser cutters, and waterjets translate the digital data into physical form with incredible accuracy. This automation eliminates human error in measurement and cutting, producing steel plates and structural components that are perfect replicas of their digital counterparts, ready for assembly.

Advanced Welding and Assembly

Welding is the critical process that joins individual steel components into a cohesive whole. Modern fabrication shops employ advanced techniques like robotic and automated welding to produce consistent, high-strength welds that meet rigorous quality standards. Jigs and fixtures, often built to tight tolerances themselves, ensure that components are held in the correct position during welding, guaranteeing the final assembly’s dimensional accuracy.

Rigorous Quality Control and Assurance

Precision is verified, not assumed. Throughout the fabrication process, a strict regimen of quality control is applied. Advanced metrology tools, including laser trackers and 3D scanners, are used to measure components and assemblies, comparing them against the original CAD models. Non-destructive testing methods like ultrasonic and radiographic inspection verify the integrity of welds, ensuring there are no hidden flaws. This commitment to quality assurance prevents costly rework and guarantees that every component leaving the shop meets or exceeds project specifications.

Precision in Practice: Applications Across Modern Infrastructure

The tangible impact of precision steel fabrication is visible in every sector of modern infrastructure. The construction and infrastructure sectors are heavily reliant on these processes, representing over 34% of sheet metal market demand.

Building Modern Transportation Hubs

Modern bridges, tunnels, and railway systems depend on the flawless fit-up of massive steel components. For a suspension or cable-stayed bridge, the precise geometry of tower sections, deck segments, and anchorages is critical to managing tension and compression forces. In rail networks, the exacting alignment of structural supports ensures smooth and safe transit at high speeds.

Powering the Future: Energy and Industrial Facilities

The energy sector, from renewable wind farms to traditional power plants, operates under demanding conditions. The support structures for massive wind turbines must be fabricated to exact tolerances to handle immense rotational forces and wind loads. In industrial facilities, precision-fabricated pipe racks, pressure vessels, and equipment skids ensure safe operation and prevent environmental hazards.

Shaping Our Skylines: Urban Development

Skyscrapers are monuments to precision. The core structural system, composed of a dense grid of steel columns and beams, must be perfectly aligned to transfer the load of hundreds of floors down to the foundation. Each of the thousands of structural components must fit seamlessly with the next. Any compounding error in fabrication could compromise the stability of the entire building, making precision a non-negotiable aspect of high-rise construction.

Safeguarding Resources: Water and Environmental Infrastructure

Large-scale water treatment plants, desalination facilities, and flood control systems rely on complex networks of steel pipelines, tanks, and support structures. The precision of these fabricated components is essential for ensuring leak-proof connections and the long-term integrity of systems that are vital for public health and environmental protection.

The Broader Impact: Economic, Environmental, and Collaborative Advantages

The benefits of precision steel fabrication extend far beyond structural performance, creating a ripple effect that improves project economics, sustainability, and collaboration.

Economic Efficiencies and Project Acceleration

Precision manufacturing minimizes on-site issues. When components arrive and fit together perfectly, assembly is faster, reducing labor costs and accelerating project timelines. This eliminates the significant expense and delays associated with rework, where ill-fitting parts must be cut, re-welded, or sent back to the shop. Getting it right the first time is the most cost-effective approach in modern construction.

Contributing to a Sustainable Future

Sustainability in construction involves minimizing waste and maximizing resource efficiency. Precision fabrication is inherently sustainable. By optimizing cutting patterns from steel plates, fabricators reduce scrap material. Furthermore, steel itself is one of the world’s most recycled materials. The steel industry demonstrates high material efficiency, with 98.15% of its raw materials in 2023 being converted into steel products or co-products. This combination of efficient manufacturing and material recyclability makes precision steel a responsible choice for modern infrastructure.

The Collaborative Ecosystem of Precision

Achieving precision requires a close, collaborative partnership between designers and builders. Engineers and architects who understand the fabrication process can create designs that are both innovative and manufacturable. In turn, expert fabricators can provide valuable feedback, identifying potential challenges and suggesting optimizations before production begins. This integrated ecosystem ensures that the final product is a true reflection of the design intent, executed to the highest possible standard.

The Future is Precisely Built: Innovation in Infrastructure Fabrication

As the demands on our infrastructure continue to intensify, the role of precision fabrication will only become more critical. The industry is constantly innovating to meet future challenges.

Continued Technological Evolution

The integration of artificial intelligence, machine learning, and advanced robotics into fabrication is set to push the boundaries of accuracy and efficiency even further. These technologies will enable predictive quality control, fully autonomous welding, and even more sophisticated manufacturing processes, allowing for the creation of structures with unprecedented complexity and performance.

Enabling the Infrastructure of Tomorrow

Future infrastructure projects—from hyperloop transportation systems to floating offshore energy platforms—will present new and complex engineering challenges. These visionary concepts will rely entirely on the ability of the fabrication industry to produce components with even tighter tolerances and more advanced material properties. Precision steel fabrication is not just supporting the infrastructure of today; it is the essential enabler of the infrastructure of tomorrow.

Conclusion

Precision steel fabrication is the invisible art and exacting science that underpins the modern world. It is the crucial discipline that ensures our skyscrapers stand tall, our bridges connect communities, and our energy systems power progress. More than just a step in the construction process, it is a fundamental commitment to safety, quality, and durability. By transforming raw steel into meticulously engineered components, precision fabricators provide the structural integrity required to turn ambitious designs into enduring realities. As we continue to build a more complex and interconnected world, the indispensable role of precision will remain the cornerstone of resilient, reliable, and remarkable infrastructure for generations to come.