Introduction: The Challenge of Wear and the Promise of Abrasion Resistant Castings

In heavy industries, the relentless battle against wear and abrasion is a constant operational challenge. From the crushing jaws of a rock quarry to the grinding mills of a cement plant, equipment components are subjected to forces that degrade, damage, and ultimately destroy them. This continuous cycle of wear leads to costly downtime, intensive maintenance schedules, and a significant drain on productivity. To remain competitive, operators increasingly turn to abrasion resistant castings — engineered materials designed not just to endure harsh conditions but to excel under extreme stress, extending service life and improving operational efficiency.

The Cost of Equipment Wear: Downtime, Maintenance, and Productivity Loss

Equipment failure is not merely an inconvenience; it is a direct and substantial financial liability. In the mining sector, for instance, unplanned downtime can be devastating. Research shows that mining companies may face losses of $130,000 per hour for every equipment failure incident, with some estimates placing the average cost per incident even higher. This financial drain is compounded by the fact that many mining manufacturers are compelled to allocate 35-50% of their annual budgets to maintenance, a significant portion of which is dedicated to replacing worn-out parts. The hidden costs—missed production targets, logistical delays, and safety risks—further underscore the critical need for components with superior longevity.

Introducing High-Chrome Cast Iron: A Solution for Demanding Environments

High-Chrome Cast Iron (HCCI) emerges as a premier materials science solution engineered specifically for these demanding environments. It is not a standard metal but a sophisticated family of alloys renowned for its exceptional hardness and abrasion resistance. By incorporating a significant percentage of chromium and other key elements, HCCI develops a unique microstructure capable of withstanding the most aggressive wear mechanisms. This makes it the material of choice for critical components that are expected to perform reliably under constant punishment. The growing reliance on this material is reflected in market trends; the global high-chromium cast iron market was valued at approximately USD 15.5 billion in 2023 and is projected to expand significantly, as noted by Dataintelo.

Why This Article Matters: Unlocking Longevity and Efficiency

This article delves into the science and practical application of High-Chrome Cast Iron parts. We will explore its composition, the metallurgical principles that grant it superior wear resistance, and its diverse applications across key industries. For engineers, maintenance managers, and procurement specialists, understanding the distinct advantages of HCCI is the first step toward maximizing equipment life, slashing maintenance costs, and boosting operational efficiency. It’s about making a strategic investment in durability that pays dividends through enhanced reliability and productivity.

Understanding High-Chrome Cast Iron: Composition and Core Properties

The exceptional performance of High-Chrome Cast Iron is not accidental; it is the direct result of a carefully engineered chemical composition and metallurgical structure. Understanding these fundamentals reveals why HCCI stands apart from other wear-resistant materials.

What is High-Chrome Cast Iron (HCWCI)? Definition and Basic Characteristics

High-Chrome White Cast Iron (HCWCI), often shortened to High-Chrome Cast Iron, is a category of cast irons containing between 12% and 30% chromium. Unlike conventional grey cast iron where carbon exists as graphite flakes, the carbon in HCWCI forms extremely hard carbides due to the influence of chromium. This results in a material with exceptionally high hardness, typically ranging from 450 to over 700 Brinell Hardness (HB), making it inherently resistant to scratching and gouging from abrasive materials. Its primary characteristic is a trade-off that favors extreme abrasion resistance, sometimes at the expense of the toughness seen in steels.

The Role of Chromium: The Primary Alloying Element for Wear Resistance

Chromium is the cornerstone of HCCI’s properties. When added to iron in sufficient quantities, it fundamentally alters the alloy’s microstructure during solidification. Instead of forming graphite, the carbon preferentially combines with chromium to create chromium carbides (specifically M7C3 carbides). These carbides are incredibly hard, often exceeding 1500 HV (Vickers Hardness), which is significantly harder than abrasive media like quartz sand. They form a network of hard particles embedded within a metallic matrix, acting as the primary defense against abrasive wear. The higher the chromium content, the greater the volume of these wear-defeating carbides.

Key Alloying Elements Beyond Chromium: Nickel, Molybdenum, and Their Contributions

While chromium is the star, other alloying elements play critical supporting roles in refining HCCI’s properties.

- Nickel (Ni) is primarily added to improve toughness and ensure the formation of a desirable matrix structure upon cooling. It helps suppress the formation of pearlite, a softer constituent, promoting a harder martensitic or austenitic matrix during heat treatment. This makes the component more resistant to chipping and cracking under moderate impact.

- Molybdenum (Mo) enhances the hardenability of the iron, meaning it can achieve high hardness more consistently through thicker sections. It also refines the carbide structure and can increase the material’s strength and corrosion resistance at elevated temperatures, broadening its application potential.

The Metallurgical Edge: Why HCWCI Excels in Wear Resistance

The superior wear resistance of High-Chrome Cast Iron is a direct function of its meticulously controlled chemical composition, microstructure, and the transformative power of heat treatment. These factors work in concert to create a material uniquely suited for abrasive environments.

Chemical Composition and Its Impact on Performance

The precise balance of carbon and chromium is critical. A higher carbon content leads to a greater volume of hard carbides, enhancing abrasion resistance. However, too much carbon can increase brittleness. The chromium-to-carbon ratio dictates the type and morphology of the carbides formed. Other elements, like molybdenum and nickel, are strategically added to influence the supporting matrix, ensuring it has the necessary hardness and toughness to hold the primary carbides firmly in place and resist deformation. The selection of raw materials of high purity is the first step in achieving this delicate chemical balance.

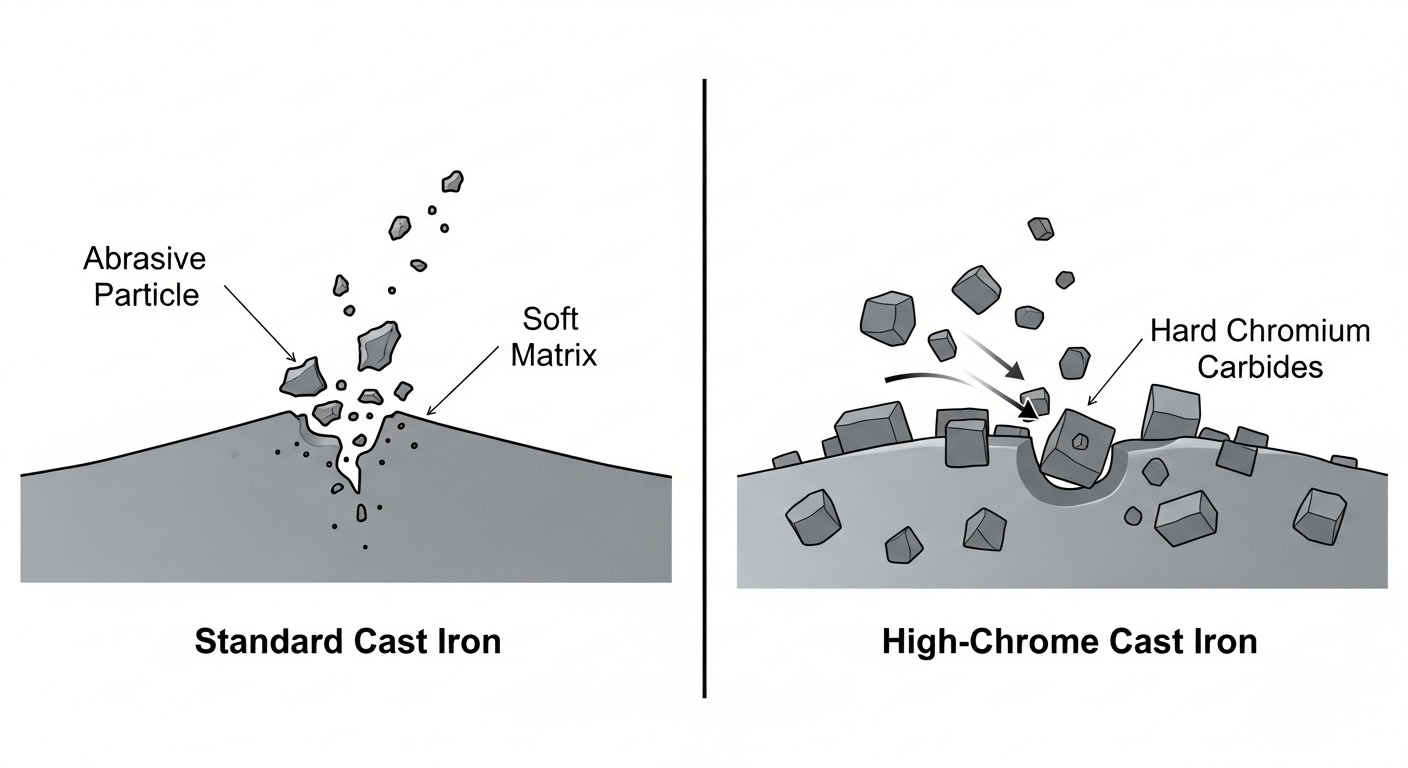

Microstructure: The Foundation of Hardness and Durability

The performance of HCCI is rooted in its two-phase microstructure: ultra-hard chromium carbides embedded within a tough metallic matrix. Imagine reinforced concrete, where the hard aggregate (the carbides) provides compressive strength and wear resistance, while the cement binder (the matrix) holds it all together. The carbides (M7C3) are the primary defense, directly resisting the cutting and ploughing action of abrasive particles. The effectiveness of these carbides, however, depends entirely on the matrix that supports them. If the matrix is too soft, the carbides can be torn out; if it’s too brittle, the entire component can fracture.

The Critical Role of Heat Treatment

In its as-cast state, the matrix of HCCI is often composed of soft austenite and pearlite, which do not provide adequate support for the carbides. Heat treatment is the essential process that unlocks the material’s full potential. The process typically involves heating the casting to a high temperature to dissolve alloying elements into the austenite, followed by a rapid cooling process known as quenching. Quenching transforms the soft austenite into hard martensite, a strong, needle-like structure that provides excellent support for the carbides. A subsequent tempering treatment may be applied to relieve internal stresses and fine-tune the balance between hardness and toughness for the specific application.

Mechanisms of Wear Resistance in HCWCI

HCCI’s superior performance stems from its ability to combat multiple wear mechanisms simultaneously. Its extreme hardness directly counters two-body abrasion (scratching from a fixed surface) and three-body abrasion (wear caused by loose particles between surfaces). The hard M7C3 carbides are significantly harder than most common abrasive minerals like silica and feldspar found in mining and construction. This hardness differential means the abrasive particles are unable to effectively cut or gouge the HCCI surface, leading to a drastically reduced rate of material loss and extended component life.

From Raw Material to Robust Part: Manufacturing High-Performance HCWCI

Creating a durable High-Chrome Cast Iron component is a process that demands precision and deep metallurgical experience. It begins with sourcing quality raw materials and extends through advanced foundry techniques and rigorous quality control.

Quality Raw Materials and Precision Alloying for Consistent Performance

The manufacturing journey starts with the careful selection of high-purity raw materials, including pig iron, steel scrap, and ferroalloys containing chromium, molybdenum, and nickel. Contaminants can compromise the final microstructure and mechanical properties. Precision is paramount during the alloying stage, where each element is added in exact quantities to achieve the target chemical composition. This meticulous control ensures that every batch of HCCI will form the desired carbide structure and respond correctly to subsequent heat treatment, guaranteeing consistent performance from part to part.

Advanced Melting and Casting Techniques

The alloyed charge is melted in induction furnaces, which allow for precise temperature control and chemical homogeneity. Once the molten metal reaches the correct temperature and composition, it is poured into molds designed to form the final component shape, such as pump casings, liners, or grinding balls. The casting technique itself, including gating and riser design, is critical to prevent defects like porosity or shrinkage, which could create weak points in the final part. The cooling rate in the mold is also controlled to initiate the formation of the primary carbide structure.

Production Efficiency and Quality Control in Foundry Goods

Modern foundries integrate efficiency with stringent quality control. Spectrometers are used to verify the chemical composition of the melt before pouring. After casting and heat treatment, parts undergo a battery of tests. Hardness testing confirms the success of the quenching process, while non-destructive methods like ultrasonic and magnetic particle inspection are used to check for internal and surface defects. This comprehensive quality assurance, backed by years of foundry experience, ensures that every HCCI part shipped meets the demanding specifications required for harsh industrial service.

Unlocking Value: Key Benefits of High-Chrome Cast Iron Parts

Choosing High-Chrome Cast Iron for wear components translates into significant, measurable advantages for industrial operations. The benefits extend beyond simple durability to encompass enhanced efficiency, reduced costs, and greater overall reliability.

Extended Equipment Life and Significantly Reduced Downtime

The most direct benefit of HCCI is its ability to dramatically extend the service life of wear parts. In applications like chutes and liners, field deployments have shown lifespans extended from a few weeks to over a year, with replacement intervals increasing from 45 days to 10 months, as documented by Sandvik Group. This longevity means fewer shutdowns for maintenance and replacement, directly translating to increased uptime and productivity. Less frequent change-outs also reduce labor costs and improve operational safety.

Cost-Effectiveness and Enhanced Operational Efficiency

While HCCI components may have a higher initial purchase price than some alternatives like standard steel, their total cost of ownership is significantly lower. The extended lifespan reduces the frequency of purchases, and the minimized downtime boosts production output. This makes HCCI a highly cost-effective solution over the long term. Equipment that maintains its critical dimensions for longer also operates more efficiently, whether it’s a pump maintaining its hydraulic performance or a crusher maintaining its desired output size.

Superior Performance in Harsh and Abrasive Environments

HCCI is specifically engineered for the worst conditions. Its microstructure provides exceptional abrasion resistance against hard, sharp materials like rock, sand, coal, and clinker. This makes it the ideal choice for industries where wear is the primary mode of failure. While materials like Manganese Steels rely on impact to work-harden, HCCI possesses inherent high hardness from the start, making it superior in sliding and grinding abrasion scenarios.

Achieving the Optimal Balance of Hardness and Impact Property

Through precise alloying and expert heat treatment, HCCI can be tailored to achieve an optimal balance of properties. While its primary strength is hardness, the addition of elements like nickel and molybdenum, combined with controlled quenching and tempering, develops a matrix with sufficient toughness to withstand the incidental impacts common in crushing, grinding, and material handling operations. This balance ensures the part resists wear without being overly brittle.

Long-Term Reliability and Lower Maintenance Costs

The predictability and durability of HCCI parts lead to greater operational reliability. Maintenance teams can plan for longer service intervals with confidence, moving from reactive repairs to a proactive maintenance strategy. The substantial reduction in component replacement, labor, and associated downtime directly contributes to a lower overall maintenance budget, freeing up resources for other critical operational needs. The growing wear-resistant materials market, projected to expand at a CAGR of 7%, underscores the industry’s shift toward such reliable solutions.

Diverse Applications: Where HCWCI Makes a Difference

The unique properties of High-Chrome Cast Iron make it indispensable across a wide range of heavy industries where abrasion is a constant challenge. Its versatility allows it to be cast into complex shapes for numerous critical components.

Mining and Aggregate Industries: The Primary Battlefield for Wear

The mining and aggregate sectors are the largest consumers of HCCI parts. Here, the material is used for crusher liners, jaw plates, and hammers that must withstand constant impact and grinding from hard rock. In grinding circuits, HCCI is the material of choice for SAG and ball mill liners and grinding balls. Slurry pumps, which transport abrasive mixtures, rely on HCCI for impellers, casings, and throatbushes to resist the intense erosive wear.

Cement and Construction: Withstanding Extreme Abrasives

In cement production, HCCI is essential for components in vertical roller mills, grinding tables, and crusher parts used to process clinker—a highly abrasive material. In the broader construction industry, it is used for wear parts in concrete mixing equipment, chutes for material transfer, and ground-engaging tools where abrasion from soil and rock is severe.

Thermal Power Generation: Battling Coal and Ash Abrasion

Coal-fired power plants use HCCI extensively in their fuel and ash handling systems. Grinding rolls and rings in coal pulverizers are made from HCCI to withstand the continuous grinding of coal. Pipes, elbows, and nozzles used to transport pulverized coal and abrasive fly ash are often lined or cast entirely from HCCI to prevent rapid erosion and failure.

Oil and Gas: Demanding Conditions for Pumps and Seals

While less common, HCCI finds niche applications in the oil and gas industry. It is used in specialized pumps that handle abrasive drilling muds or proppants during hydraulic fracturing. The material’s hardness and wear resistance are also beneficial for certain types of mechanical seals and components in downhole tools that experience abrasive wear.

Other Industrial Applications: Expanding HCWCI’s Reach

The application of HCCI continues to expand. It is used in the steel industry for hot strip mill work rolls, in brick and clay manufacturing for augers and extruder dies, and in recycling facilities for shredder hammers and wear plates. Essentially, any industry that involves the grinding, crushing, or transportation of abrasive solids can benefit from the superior longevity offered by High-Chrome Cast Iron parts.

Conclusion

High-Chrome Cast Iron stands as a testament to the power of materials science in solving real-world industrial challenges. Its superior wear resistance is not a singular quality but the result of a meticulously engineered system: a high concentration of chromium to form ultra-hard carbides, a tough supporting matrix fortified by elements like nickel and molybdenum, and a transformative heat treatment process that unlocks its full potential. For industries grappling with the immense costs of equipment wear—from mining and cement to power generation—HCCI offers a clear path to enhanced productivity and reduced operational expenditures.

By extending the life of critical components like liners, pumps, and grinding balls, HCCI directly minimizes costly downtime and lowers the total cost of ownership. This shift from frequent replacement to long-term reliability allows businesses to operate more efficiently and predictably. When selecting wear parts, a focus on the upfront cost is short-sighted. The true value lies in longevity and performance. Investing in high-quality High-Chrome Cast Iron components is a strategic decision to maximize equipment life, improve operational resilience, and secure a more profitable future in the face of relentless abrasion.