Introduction: The Unseen Force Driving Modern Manufacturing Profitability

In a global marketplace defined by relentless competition and razor-thin margins, modern manufacturing success hinges on two interconnected pillars: precision and profit. The ability to produce complex components with flawless accuracy, day after day, is no longer a luxury—it is the engine of financial viability. Hidden in plain sight, the unseen force driving this capability is Computer Numerical Control (CNC) machining. This technology has quietly revolutionized factory floors, transforming the very economics of production by turning digital designs into tangible, profitable products with unparalleled exactitude. The global CNC machine market’s projected growth to USD 194.3 billion by 2034 underscores its critical role as a cornerstone of modern industry.

Beyond Manual: A Paradigm Shift in Manufacturing Efficiency

The leap from manual machining to CNC represents a fundamental paradigm shift. Where traditional methods relied on the skill, and inherent variability, of a human operator, CNC machining introduces automation and digital control. This transition eliminates the inconsistencies of manual work, replacing them with a manufacturing process that is faster, more reliable, and endlessly repeatable. The result is a dramatic increase in operational efficiency, allowing manufacturers to produce more, with fewer errors, in less time.

Defining “Precision & Profit” in Today’s Competitive Landscape

In the context of modern manufacturing, “precision” is the quantifiable ability to meet exacting design specifications consistently. “Profit” is the direct financial outcome of that precision. The two are inextricably linked. Precision reduces material waste, minimizes costly rework, and enhances product quality, all of which directly bolster the bottom line. It enables the creation of higher-value components for demanding industries, opening new revenue streams and building a reputation for reliability that translates into a powerful competitive advantage.

Understanding Computer Numerical Control (CNC) Machining: The Foundation

At its core, CNC machining is a subtractive manufacturing process that uses computer-controlled machines to remove material from a solid workpiece, shaping it into a desired part. This automated control is what distinguishes it from traditional methods, providing the foundation for its numerous advantages in speed, accuracy, and versatility.

What is CNC Machining? (Computer Numerical control, manufacturing process, CNC machines)

Computer Numerical Control (CNC) machining automates the control of machine tools through pre-programmed software. The manufacturing process involves a wide array of tools, such as mills, lathes, routers, and grinders, all directed by a computer. Instead of a human operator manually guiding the cutting tool, CNC machines follow a coded set of instructions. This allows for the creation of components with a level of complexity and precision that is virtually impossible to achieve by hand, making it indispensable for modern manufacturing operations.

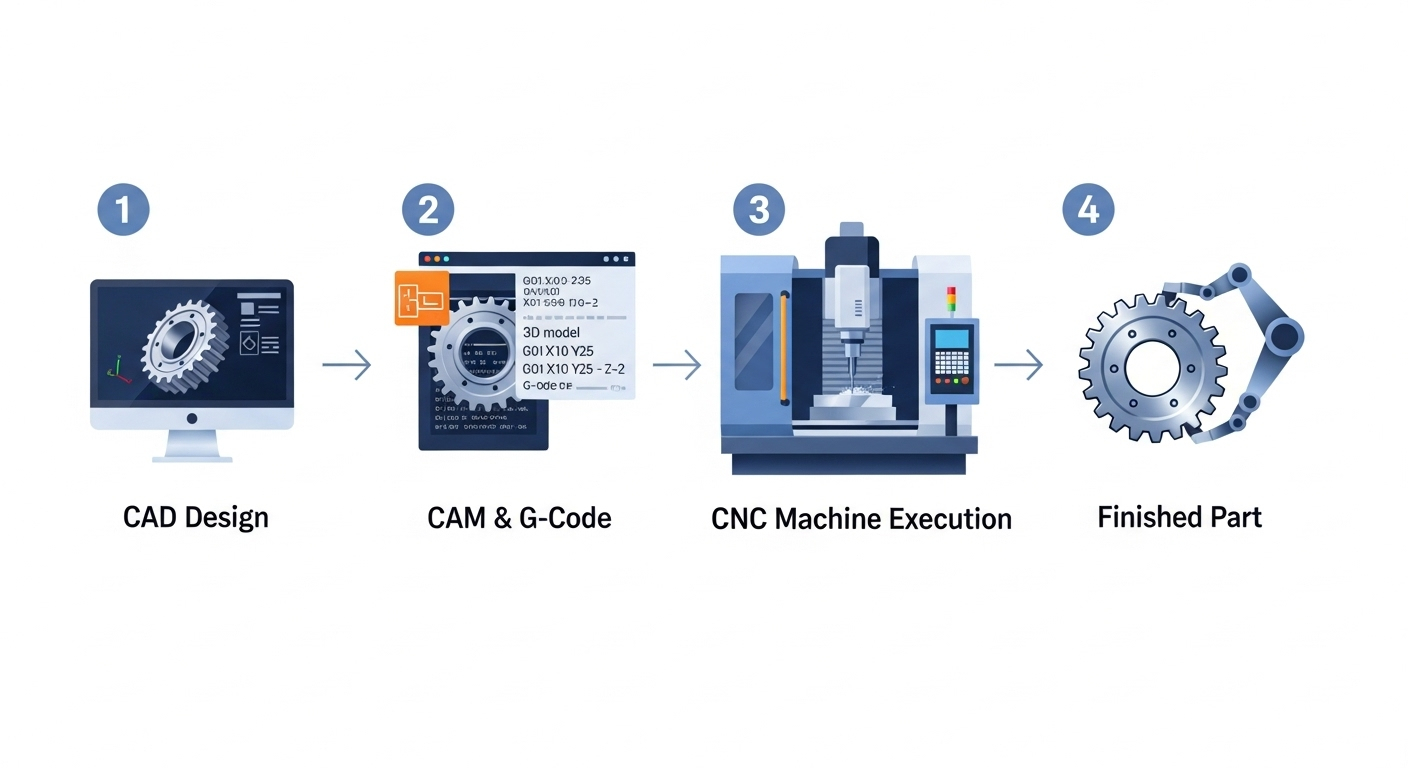

The Core Mechanism: How it Works (CAD software, CAM software, G-code, tool paths, computer-aided design, computer-aided manufacturing)

The CNC workflow begins with a digital design. First, an engineer creates a 2D or 3D model using Computer-Aided Design (CAD) software. This digital blueprint is then processed by Computer-Aided Manufacturing (CAM) software, which converts the model into a detailed set of instructions for the CNC machine. These instructions, known as G-code, dictate every aspect of the operation: the movement of the tool (tool paths), the speed of the spindle, the rate of feed, and when to turn coolant on or off. The G-code is loaded into the machine’s controller, which then executes the program, guiding the cutting tool with microscopic precision to shape the final part.

Precision as the Cornerstone of Profitability

The primary value proposition of CNC machining is its extraordinary precision, which serves as the bedrock of its profitability. Every benefit—from reduced waste to enhanced product reliability—stems from the machine’s ability to execute commands with near-perfect accuracy and consistency.

Achieving Unmatched Accuracy and Repeatability (Accuracy, precision, tolerances, servo motors, feedback mechanisms)

CNC machines achieve superior accuracy and precision through a combination of rigid construction, high-performance servo motors, and sophisticated feedback mechanisms. These systems allow the machine to maintain incredibly tight tolerances, often measured in microns. Accuracy refers to how closely a cut matches the specified dimension, while repeatability is the machine’s ability to produce the exact same cut time and time again. This consistency is crucial for mass production, ensuring that the thousandth component is identical to the first, a feat unattainable with manual methods.

Eliminating Waste and Rework: Direct Cost Savings (Reducing operator error, material waste, minimizing production errors)

Precision directly translates into significant cost savings by drastically reducing waste. By minimizing production errors from the outset, CNC machining slashes the need for costly rework or scrapped parts. Human operator error is virtually eliminated from the cutting process, and optimized tool paths generated by CAM software ensure the most efficient use of raw material. This reduction in material waste and rejected components flows directly to the bottom line, improving margins and making the entire manufacturing process more financially sustainable.

The Impact on Quality Control and Product Reliability (Higher product value, consistency, brand reputation, design retention)

Consistent precision elevates overall product quality and reliability. When components are machined to exact specifications every time, they perform as designed, leading to a more dependable final product. This reliability enhances the product’s perceived value and strengthens brand reputation. Furthermore, the digital nature of the process ensures perfect design retention; the specifications from the CAD file are flawlessly translated into every physical part, guaranteeing that the original design intent is maintained throughout the entire production run.

Risk Mitigation through Precision Engineering (Reducing product failure, recalls, and associated financial losses)

In high-stakes industries like aerospace and medical, component failure is not an option. CNC machining provides the precision engineering necessary to mitigate these risks. By manufacturing components that adhere strictly to design tolerances, manufacturers can significantly reduce the likelihood of product failure, subsequent recalls, and the immense financial and reputational damage that follows. This level of control is essential for producing the critical components that power modern technology safely and reliably.

Efficiency & Speed: Accelerating Market Entry and Maximizing Output

In addition to precision, CNC machining delivers transformative gains in speed and efficiency. By automating and streamlining the manufacturing process, it enables companies to increase throughput, shorten lead times, and bring products to market faster than their competitors.

Streamlined Production Cycles and Reduced Setup Times (Setup time, manufacturing process, faster throughput, production volume)

CNC machines are designed for efficiency. Advanced features like automatic tool changers and pallet systems can dramatically reduce setup time between jobs. Once a program is loaded and verified, the machine can run continuously with minimal operator intervention, often 24/7. This continuous operation leads to faster throughput and a significant increase in production volume compared to traditional methods, allowing manufacturers to meet demanding deadlines and scale operations effectively. The integration of AI is pushing this even further, with the potential to reduce CNC cycle times by about 20%.

From Prototypes to Production: Rapid Development and Iteration (Prototyping, prototypes, faster time-to-market, computer-aided design)

CNC machining is a powerful tool for innovation, excelling at both rapid prototyping and full-scale production. A design created in CAD software can be quickly machined into a physical prototype for testing and validation. If modifications are needed, the digital file can be easily updated and a new iteration produced within hours or days. This agile development cycle drastically shortens the time-to-market for new products, giving manufacturers a critical edge in fast-moving industries.

Unlocking Design Freedom and Material Versatility for Competitive Advantage

CNC machining liberates designers and engineers from the constraints of traditional manufacturing methods. Its ability to handle a vast range of materials and create highly complex shapes provides a significant competitive advantage, enabling the development of innovative and optimized products.

Crafting Complex Geometries with Ease (Complex components, multi-axis machining, 5-axis CNC machines, detailed parts)

Modern multi-axis CNC machines, particularly 5-axis models, can approach a workpiece from multiple directions in a single setup. This capability allows for the creation of incredibly complex components and intricate geometries that would be impractical or impossible to produce otherwise. From curved surfaces to detailed internal features, CNC machining empowers engineers to design parts optimized for performance, weight, and function, rather than being limited by manufacturing constraints. This trend is reflected in the market, where demand for high-end CNC machines capable of producing customized, miniaturized components saw a 25% surge in 2024.

Strategic Industry Applications: Where CNC Drives Specific Profits

The advantages of CNC machining are not theoretical; they are proven daily across the world’s most demanding industries. In the aerospace sector, it is used to craft lightweight, high-strength structural components and intricate engine parts where precision is paramount for safety and fuel efficiency. In fact, CNC machines contributed to a 15% increase in productivity in U.S. aerospace manufacturing between 2019 and 2024. The medical field relies on CNC for creating custom implants, surgical instruments, and prosthetics from biocompatible materials with life-or-death accuracy. For the automotive industry, which is projected to remain the dominant application area with revenues exceeding $20 billion by 2025, CNC delivers the consistency needed for mass-producing engine components and the versatility for rapid prototyping of new vehicle designs. In electronics, it produces precise housings and connectors essential for the function of modern devices.

The Future of CNC: Sustaining Precision and Maximizing Profit in Industry 4.0

The evolution of CNC machining is far from over. As part of the Industry 4.0 revolution, CNC machines are becoming smarter and more connected. Integration with the Internet of Things (IoT) allows for real-time monitoring and predictive maintenance, minimizing downtime. The growing role of artificial intelligence and machine learning is optimizing tool paths and production schedules for even greater efficiency. These advancements ensure that CNC machining will remain a vital, profit-driving technology, continuing to offer manufacturers a path to sustained competitive advantage.

Conclusion: CNC Machining as a Strategic Imperative for Modern Manufacturers

In the final analysis, CNC machining is far more than just another manufacturing process; it is a strategic imperative for any manufacturer serious about competing in the modern era. It provides a direct and powerful solution to the core challenges of production: the simultaneous demand for higher quality, greater speed, and lower costs.

Recap of Definitive Advantages (Reiterating the synergy of precision, efficiency, versatility, and strategic profit drivers)

The definitive advantages of CNC machining create a powerful synergy. Unmatched precision reduces waste and enhances product quality. Automation-driven efficiency accelerates production cycles and increases throughput. Unrivaled versatility in materials and geometries unlocks design innovation. Together, these pillars are not just operational benefits; they are strategic profit drivers that build resilient, competitive, and successful manufacturing enterprises.

The ROI of Embracing Advanced CNC (Long-term investment, competitive edge, sustained growth, enhanced manufacturability)

While the initial investment in CNC technology can be significant, the return on investment is compelling and multifaceted. It comes from direct cost savings in material and labor, increased revenue from higher output, and the ability to secure contracts in high-value industries. Embracing advanced CNC is an investment in a long-term competitive edge, enhanced manufacturability, and a foundation for sustained growth.

Strategic Partnership for Precision and Profit (Emphasizing the importance of choosing the right CNC solutions and expertise)

Maximizing the benefits of this technology requires more than just purchasing a machine. It requires a strategic approach to implementation and a partnership with experts who understand the nuances of CNC solutions. Choosing the right equipment, software, and skilled personnel is critical to fully leveraging the power of precision to drive profit and secure a leading position in the market.