Quick Summary

CNC machine pricing isn’t one-size-fits-all—costs vary dramatically based on size, complexity, precision, and software capabilities. This guide breaks down different machine types from entry-level desktop models to multi-axis industrial workhorses used in aerospace and automotive. You’ll learn how features like speed, material compatibility, and brand reputation influence pricing, and how operating costs like maintenance, tooling, training, and energy can impact your bottom line. If you're debating between buying or outsourcing, you'll also find insights to help make the call—with Dews Foundry’s cnc machining services standing out as a trusted partner in precision manufacturing.

Navigating the labyrinthine world of CNC machine pricing can be as daunting as deciphering the design specs of a new aerospace-grade vertical mill. How much is a CNC machine, you ask? Well, let’s just say it’s not as straightforward as a grocery list—the costs can swing widely depending on specific requirements, industry standards, and technological bells and whistles.

This article unpacks the myriad factors that influence CNC machine costs, from the straightforward size and complexity to those delightful surprises in accuracy and software capabilities that sometimes leave procurement leads questioning their life choices. As someone well-versed in the nuances of machinery acquisition, you’ll appreciate our examination of the different types and sizes of CNC machines, ultimately guiding you through comparing costs for entry-level models versus advanced industrial workhorses.

With your need for precision and efficiency in mind, we’ll delve into industry-specific machines and additional operating costs, weighing the eternal ‘buy vs. outsource’ debate with the exactitude that only professional experience can provide. Not to worry, we’ll be referencing Dews Foundry’s expertise in cnc machining. To further ground our discussion in the realm of facts, expect insights from reputable sources like the U.S. Department of Commerce, ensuring you walk away with a deeper understanding, rather than just sticker shock.

Key Factors Influencing CNC Machine Costs

When determining how much a CNC machine costs, several critical factors come into play. From the sheer size of the machine to the intricacy of its design, each element can significantly impact the financial outlay required for these industrial marvels. Understanding these factors helps procurement leads and shop managers make informed decisions when investing in advanced machinery. Let’s delve deeper into each aspect to uncover the nuances affecting CNC machine pricing.

Size and Complexity

The size and complexity of a CNC machine substantially influence its cost. Larger machines, such as multi-axis vertical mills or gantry-style systems, inherently command a higher price due to the volume of materials used and the advanced engineering that accompanies larger builds. Complexity also plays a decisive role; machines with intricate designs and numerous moving parts require specialized engineering, which adds to the cost.

It’s like buying a high-end sports car; you get superior performance but also need the budget to match its complexity and sophistication. Industrial-scale machines are perfect examples of such over-engineered wonders, where the price tag can sometimes be as substantial as the equipment itself—surprisingly hefty and appropriately so.

Accuracy and Speed

Accuracy and speed are pivotal to CNC machine performance. Machines boasting high precision and rapid operation capabilities typically demand a higher investment. The reason behind this premium is the sophisticated technology and advanced mechanics involved in delivering tight tolerances and quick turnaround times. Such machinery is essential for sectors where top-notch precision is mandatory, like aerospace or medical device manufacturing.

In the world of CNC, faster can indeed equate to more efficient production, as long as it does not come at the expense of accuracy. For those hesitant about the high costs, remember: You wouldn’t want to trade off speed for an inexact replica of your carefully crafted designs.

Material Compatibility

The ability of a CNC machine to handle a wide variety of materials expands its functionality but also affects its price. Machines optimized for cutting metals, composites, or specific materials like carbon fiber or G10 are engineered with these materials in mind, necessitating durable, high-grade components that justify their price tag.

Material compatibility ensures operational versatility. An investment in a machine capable of handling diverse materials can expand your shop’s capabilities, ultimately leading to better long-term returns. After all, a jack of all trades sometimes is a master in its domain—particularly when crafted by experts.

Brand Reputation

Branding is another significant consideration impacting CNC machine costs. Well-known and respected manufacturers often sell machines at a premium due to their reliable track records and customer support. These brands have established themselves by offering durable and highly efficient machinery, providing customers with confidence in their investment.

Though it might seem tempting to consider less expensive alternatives from lesser-known suppliers, the presumed savings can sometimes vanish alongside unexpected maintenance costs. Trust that when brand reputation is at stake, an informed decision about initial costs might save significant future headaches.

Advanced Features and Software

Advanced features and integrated software solutions not only enhance the operational capacity of a CNC machine but also contribute heavily to its cost. Built-in automation capabilities, high-speed processing suitable for production-ready environments, and machine learning software for predictive maintenance are just a few features that can increase the value proposition of a CNC machine.

These advanced tools turn CNC machines into intelligent industrial assets, allowing them to perform at unprecedented efficiency levels. Features like these ensure that your equipment doesn’t just keep up with industry standards—it’s constantly pushing the boundaries to meet evolving demands. Consider it a worthy investment for staying on the cutting edge of manufacturing technology.

Ultimately, when thinking about CNC machines, collaborating with established partners such as cnc machining at Dews Foundry can provide the assurance that comes with decades of expertise, offering custom solutions and supporting your production needs without the overhead of owning the equipment outright. For further insights on manufacturing technologies and trends, resources like the NIST study on manufacturing tech could provide valuable information.

CNC Machine Categories and Pricing

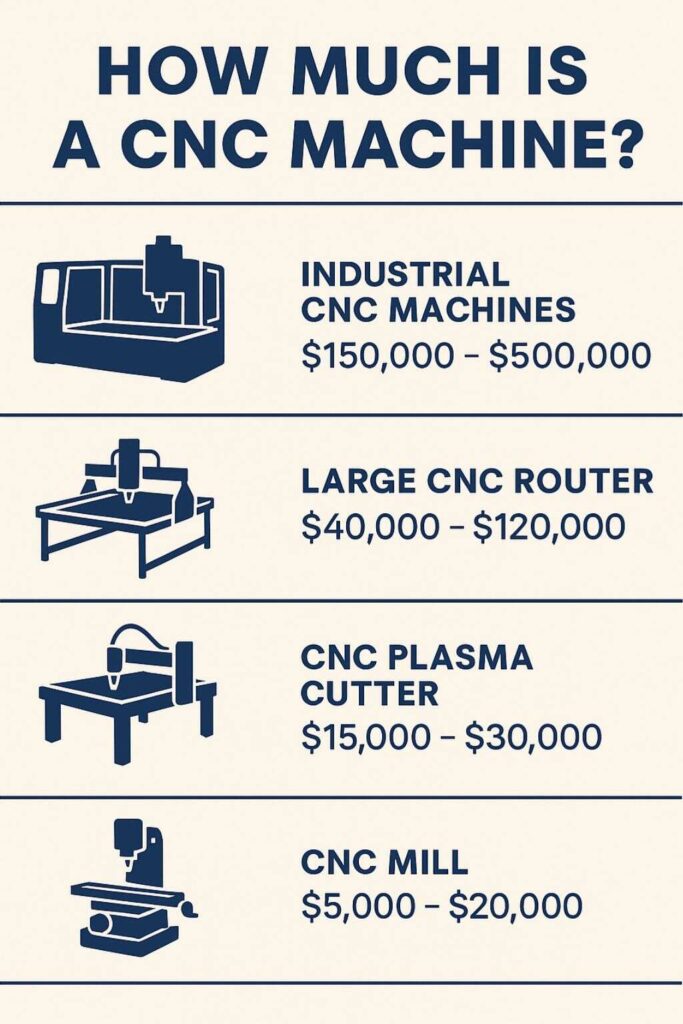

How much is a CNC machine—is there a more dreaded question for a shop manager or procurement lead evaluating industrial machinery? The answer can be as variable as the applications these machines serve. For those in the manufacturing, heavy industry, or supply chain sectors, understanding the cost spectrum of CNC machines is not just beneficial; it’s essential for financial planning and operational efficiency. Ranging from entry-level desktop models suited for hobbyists to high-end production centers in aerospace, the budget varies significantly. Let’s break it down into manageable categories.

Entry-Level Desktop CNC Routers

Entry-level desktop CNC routers are the perfect gateway for hobbyists or small-scale entrepreneurs looking to dip their toes in CNC technology without breaking the bank—or accidentally commandeering half the workshop’s budget for automation. These machines typically range from $1,000 to $4,000. They’re compact, user-friendly, and ideal for crafting small parts or prototypes in materials like plastic, wood, and softer metals. Although lacking the robust capabilities of their industrial-grade counterparts, they provide a solid foundation for understanding CNC operations without the risk of accidentally instigating a company-wide financial audit.

Prosumer and Professional Prototyping Models

In the intermediate tier, prosumer and professional prototyping models provide enhanced capabilities, catering to small businesses and professional fabricators in need of more precision and power. While still manageable in price, with figures ranging between $5,000 and $25,000, these machines offer features like Automatic Tool Changers and support for stiffer materials such as carbon fiber and a variety of composites. While you might not be able to brag about owning the latest high-speed machinery, these models strike a fine balance between cost and capability, making them ideal for crafting prototypes with reasonably tight tolerances without investing a fortune in additional costs like complex power supplies or material storage solutions.

High-End Production Machining Centers

At the pinnacle of CNC machinery, high-end production machining centers redefine what’s possible in modern manufacturing facilities. These behemoths, including multi-axis vertical mills and gantry-style machines, are essential for industries demanding meticulous precision—such as aerospace or complex automotive components. However, they come with a justifiably intimidating price tag. Typically ranging from $50,000 to well over $500,000, these machines are not simply purchased but rather invested in—akin to buying a home rather than renting a garage workshop. For procurement leads, navigating these costs can feel like negotiating a peace treaty in high-stakes finance. The extensive capabilities of these machines—supported by built-in automation and rapid production iterations—are critical for mass production and have the power to transform your operations from merely capable to industry-leading.

To further understand how such investments translate into operational success, a trusted provider like Dews Foundry can guide you through the intricacies of cnc machining and custom fabrication, ensuring you remain competitive in today’s ever-evolving industrial landscape. For additional insights into manufacturing technologies, it’s worth exploring academic resources such as reports by the U.S. Department of Commerce, which provide invaluable data and metrics to support your decision-making process.

Industry-Specific CNC Machines

In the modern manufacturing landscape, industry-specific CNC machines have become indispensable in optimizing processes, reducing waste, and achieving the highest levels of precision. From woodworking to metalworking, and into the realms of laser and plasma cutting, CNC technology has redefined what’s possible on the production floor. Yet, as we invest in these marvels of modern technology, it’s crucial to understand their specific applications, operational benefits, and, of course, their cost implications. After all, purchasing a CNC machine is not just a drop in the bucket—it’s a substantial investment that can significantly impact operational efficiency and returns.

CNC Routers for Woodworking

CNC routers have revolutionized the woodworking industry through their ability to create intricate designs with unparalleled accuracy. These machines offer versatility, allowing for the precise carving of detailed furniture components, signage, and even musical instruments. To the surprise of many, entry-level models can be relatively affordable, making them accessible for smaller businesses or those looking to incorporate CNC technology without breaking the bank. While higher-end routers can cost upwards of tens of thousands of dollars, their output precision and time-saving capabilities often justify their price tag, especially for volume production.

CNC Lathes for Metalworking

CNC lathes are the quintessential workhorses of the metalworking industry, perfectly suited for shaping complex metal components with tight tolerances. These machines excel in producing cylindrical parts and are critical in industries ranging from automotive to aerospace. Investing in a CNC lathe can indeed seem like financing a small spacecraft. Multi-axis models, which enable more complex machining work, can easily cost into the six-figure range. However, for a shop manager weighing the return on this significant investment, the ability to produce complex geometries with precision often tips the scale towards the affirmative.

Laser and Plasma Cutters

Laser and plasma cutters provide exceptional capabilities for cutting through metal with speed and precision. These machines are widely used for fabrication tasks that demand clean cuts and intricate detailing. It’s often encountered in metal shops where steel and aluminum are the materials of choice, or in industries that explore materials like G10 and phenolic composites. Imagine telling your finance department that a single piece of equipment could cut like a hot knife through butter—only, of course, after they’ve recovered from the sticker shock of its price. Specialized models for heavy-duty applications are on the higher end of the budget spectrum, rivaling sports car prices, but their efficiency and precision in heavy industrial applications can be unrivaled.

Milling Machines

When it comes to milling machines, their role in industrial manufacturing cannot be overstated. They handle cutting, drilling, and face milling, providing essential versatility to the industrial operations. There are numerous types of milling machines: from compact machines suitable for a hobbyist’s garage workshop to hefty, multi-axis vertical mills that are the heartbeat of a production facility. Industrial-grade multi-axis vertical mills, with their jaw-dropping price tags, may resemble something closer to a spacecraft’s flight deck. However, their high-speed production capabilities and unmatched precision justify their financial heft for those pursuing tight tolerances and large-scale operations.

To delve deeper into how CNC machining services can cater to specific needs in manufacturing and fabrication, consider exploring trusted providers like Dews Foundry, known for their expert CNC machining and custom fabrication services. Additionally, for more comprehensive insights into the cost implications of CNC technology in manufacturing, the National Institute of Standards and Technology (NIST) offers an excellent resource here.

Additional Operating Costs

Navigating the world of CNC machinery is akin to solving a complex machining puzzle. Just when you think you’ve gauged all costs, additional operating expenses stealthily emerge, occasionally catching even seasoned procurement professionals off-guard. These costs, often invisible at first glance, play a substantial role in the total cost of ownership for any CNC apparatus. As efficiencies and productivity soar with these high-tech marvels, your financial outlay doesn’t end with the purchase price. Instead, a gradual series of operational expenditures quietly rally in the wings, poised to inflate the budget. Let’s delve deeper into the various facets of these supplementary costs, where maintenance, software, tooling, training, and energy consumption eagerly await their moment in the spotlight.

Maintenance and Repairs

When you procure a CNC machine, maintenance isn’t merely a suggestion—it’s an art form. From day one, machines require regular TLC to stay at peak performance. Without it, you may find yourself shelling out for repairs more frequently than anticipated, and believe me, those maintenance bills are about as welcome as a mandatory workshop safety seminar on a Friday afternoon. However, regular maintenance schedules mitigate the frequency of major repairs, extending the lifespan of the equipment.

The need for maintenance dovetails with inevitable repairs—reminding a shop manager of their unwelcome appearances like those hidden fees in a hotel bill you only find when you check out. Establish a robust maintenance program to minimize unexpected machine downtimes, effectively balancing out the operating costs over time. This proactive approach leads to a more predictable expenditure pattern, making budget management a tad less stressful.

Software and Tooling

Acting as the brains behind the brawn of CNC machines, software and tooling are integral to operating these sophisticated beasts. Most CNC machines come with basic software, but additional software purchases are often necessary for specialized applications. These may include CAD (Computer-Aided Design) or CAM (Computer-Aided Manufacturing) software, which often come with their own licenses and subscription fees. For a shop manager considering profitability, a thorough evaluation of necessary software tools becomes crucial in foreseeing operating costs.

Tooling, involving cutters and various attachments, frequently needs updating or replacement. These are consumables, subjected to wear and tear, much like how office printer cartridges mysteriously vanish just as you’re about to print an important report. Regular inventory assessments ensure that tooling costs are in check, preventing exorbitant spikes in operating expenses, thus sustaining a consistent production rhythm.

Training and Skill Development

An investment in advanced machinery like CNC is also an investment in people. Your team will need both initial training and ongoing educational updates to tackle new and advanced workflows confidently. This training can involve professional courses, workshops, or even sending your brightest minds to conferences—a necessity that’s about as cheap as those organic, gluten-free treats the finance team insists on during meetings.

By viewing training as an investment, rather than an expense, procurement leads and shop managers can cultivate an adept workforce. This ensures not only the proficient handling of complex machine activities but also fosters innovation and process improvements. Skilled operators can exploit the machine’s capabilities to their fullest, ultimately providing a competitive advantage that offsets the training costs.

Energy Consumption

Powering a CNC machine is far from an incidental detail; energy consumption is a substantial component of operating costs. Given their scale and functionality, industrial CNC machines devour electricity much like a hummingbird feasts on sugar water—swiftly and with great gusto. Factoring in the energy demands when assessing the financial feasibility of machine acquisition is essential.

Industrial CNC machines, such as multi-axis vertical mills or gantry-style systems, have varying levels of energy consumption influenced by the complexity and duration of tasks. Monitoring these metrics can aid in optimizing operation schedules to exploit off-peak energy pricing, thereby reducing overall energy expenditures. The careful orchestration of machine operation can result in noticeable cost savings, making an otherwise daunting line item a bit more palatable within the production budget.

Buy vs. Outsource CNC Machining

In the realm of industrial manufacturing, the decision to buy or outsource CNC machining can significantly impact your budget and operational efficiency. The prospect of purchasing a CNC machine might be appealing due to potential long-term cost savings and greater control over production quality. However, outsourcing to an expert provider like Dews Foundry ensures you can leverage cutting-edge technology without the hefty upfront investment. Often, the intricacies of your operations and the specifics of your production demands will determine the most financially sound path forward.

Budget Considerations

Evaluating budget constraints is crucial when deciding whether to purchase CNC machinery or outsource. Acquiring a CNC machine is a significant capital expenditure, and understanding “how much is a CNC machine” becomes crucial. High-end multi-axis machines used in aerospace can cost well into seven figures — and budget surprises are akin to an engineer’s worst nightmare, like realizing you’ve left the hydraulics on while going for lunch.

Semi-professional models suitable for mid-sized production might range from $50,000 to $150,000. Meanwhile, entry-level options for smaller operations may cost $25,000 to $50,000. Outsourcing eliminates the initial purchase cost but may include service fees. Consider long-term operational costs, including maintenance, operator training, and facility adjustments.

Production Needs and Capacity

Assessing production needs and capacity is vital in making the decision between in-house machining and outsourcing. If your shop handles high-volume, specialized workloads, buying a CNC machine might offer advantages in production speed and flexibility. When faced with work involving tight tolerances and complex geometries, equipment such as a high-speed 5-axis CNC milling machine could be indispensable.

However, if your production needs fluctuate or you manufacture products with varying complexity, outsourcing offers flexibility without tying down resources. For example, Dews Foundry provides comprehensive cnc machining services, ensuring your project’s precision without the burden of maintaining an industrial-grade machine. The choice hinges on whether the in-house capacity aligns with demand variation, sparing your budget from unnecessary excesses, much like avoiding a large forklift when a hand truck suffices.

Conclusion: Making an Informed Decision

When it comes to choosing the right CNC machine for your operation, making an informed decision is paramount. The landscape of CNC machinery varies extensively, from economically accessible options suitable for smaller projects to advanced multi-axis machines designed for high-end aerospace applications. Let’s not forget that pricing surprises often lurk in the details of project requirements and machine-specific capabilities.

Understanding your operational needs is essential. Are you considering a machine for tight tolerances and sharp edges or do you need built-in automation to streamline your workflow? Each choice can significantly impact your bottom line, both directly and through additional costs like material storage or power supply adjustments.

Here’s a brief comparison to guide your decision:

CNC Machine Type | General Cost Range ($) |

|---|---|

Hobby-Level | 1,000 – 3,000 |

Mid-Tier Production 5-Axis | 50,000 – 150,000 |

Multi-Axis Vertical Mill | 300,000 – 800,000 |

Aerospace-Grade Gantry | 1,000,000+ |

Ultimately, the right CNC machine balances performance and cost-effectiveness. For custom machining needs, Dews Foundry offers expert solutions, ensuring your production line achieves precision and efficiency. As a bonus, staying updated on manufacturing tech trends through resources like the U.S. Department of Commerce can provide valuable insights.

Frequently Asked Questions

How much does a basic CNC machine cost?

Entry-level hobby CNC machines typically range from $2,000 to $10,000 depending on size and build quality.

Why are industrial CNC machines more expensive?

Industrial CNC machines can cost between $50,000 and $500,000 due to precision, automation capabilities, build material, and application-specific features.

Do CNC machine prices include software and tooling?

Not always. Software, tooling, and installation can add significantly to the base price of the machine.

Can CNC machines be financed or leased?

Yes. Many manufacturers and distributors offer financing or leasing options, especially for high-ticket industrial units.

Is there a cost difference between CNC plasma, router, and milling machines?

Absolutely. CNC routers are often cheaper, while plasma cutters and mills vary widely based on use case and size.