Introduction: Navigating the World of Machining for Your Project

From intricate aerospace components to custom automotive parts, turning a digital design into a physical product requires a unique blend of artistry and engineering. This transformation is the domain of the skilled machinist, and knowing how to choose a machinist is crucial for project success. As the global CNC machining industry is projected to grow significantly, potentially reaching $92.4 billion by 2025, understanding how to choose a machinist has never been more important. The right choice can lead to unparalleled quality and efficiency, while the wrong decision about how to choose a machinist can result in costly delays, material waste, and compromised products.

The Critical Role of a Skilled Machinist in Project Success

A machinist is more than just an operator of machines; they are a critical partner in the manufacturing process. A skilled professional interprets complex blueprints, selects the appropriate tool and material, and executes precise cuts and finishes to create a final component. Their expertise directly influences the structural integrity, functionality, and aesthetic quality of your products. They are problem-solvers who can often identify potential design flaws or suggest more efficient manufacturing methods, saving both time and money.

Why Choosing the Right Machinist Matters for Your Bottom Line and Quality

Selecting the right machinist is a strategic decision that reverberates through your entire project. A highly competent machinist ensures that parts are made correctly the first time, minimizing scrap and rework. This commitment to quality translates directly to lower costs and faster turnaround times. Conversely, a poor choice can lead to missed deadlines, budget overruns, and products that fail to meet specifications. In competitive industries where performance is paramount, the precision delivered by a top-tier machinist can be the defining factor between a successful product launch and a costly failure.

Section 1: Defining Your Project’s Needs – The Blueprint for Selection

Before you can find the right machinist, you must have an unambiguous understanding of your own requirements. A detailed project definition acts as your primary communication tool and the foundation for a successful partnership.

Clearly Articulating Your Project Scope and Goals

Start by outlining the purpose of your project. Are you creating a one-off prototype, a small batch of custom parts, or a large-scale production run? Document the intended application of the final products, as this context helps the machinist understand critical functional requirements. Provide comprehensive 2D blueprints and 3D CAD models that clearly define every dimension, feature, and assembly instruction. The U.S. manufacturing sector is a massive economic driver, contributing $2.90 trillion to the economy in Q1 2025, and clarity at this stage upholds the standards that fuel this engine.

Material Considerations: Matching Machinist Expertise to Your Medium

The material you choose dictates the required machining processes, tools, and expertise. Common metals like aluminum and steel have different properties than titanium, brass, or specialized alloys. Similarly, plastics and composites require unique handling. A machinist specializing in aerospace-grade titanium may not be the best fit for a project involving Delrin or PEEK. Clearly specify the exact material grade and any required heat treatments or post-processing finishes. Ensure your potential machinist has demonstrable experience working with your chosen medium.

Precision, Tolerances, and Surface Finish Requirements

Machining is a game of microns. Define the acceptable dimensional tolerances for every critical feature on your blueprints. Are you working with standard tolerances, or does your project demand extremely tight precision? Specify the required surface finish (e.g., Ra value), as this impacts the tool selection, machining time, and ultimately, the cost. A machinist must have the right equipment and measurement tools (calipers, micrometers, CMM machines) to verify that these precise requirements are met.

Budget and Timeline Realities: Setting Realistic Expectations

Be transparent about your budget and timeline. This allows potential machinists to provide realistic quotes and assess if they have the capacity to meet your deadlines. Understand that a rush job often commands a premium. Likewise, extremely high-precision jobs require more time for setup and quality control. Providing a target cost-per-part for production runs can help a shop determine the most efficient machining strategy. Clear financial and temporal boundaries prevent misunderstandings and ensure the project remains viable for both parties.

Section 2: Understanding Machinist Specializations – Finding the Right Expertise

Not all machinists are the same. The field is diverse, with specialists who focus on different technologies and techniques. Understanding these distinctions is key to finding the right skill set for your jobs.

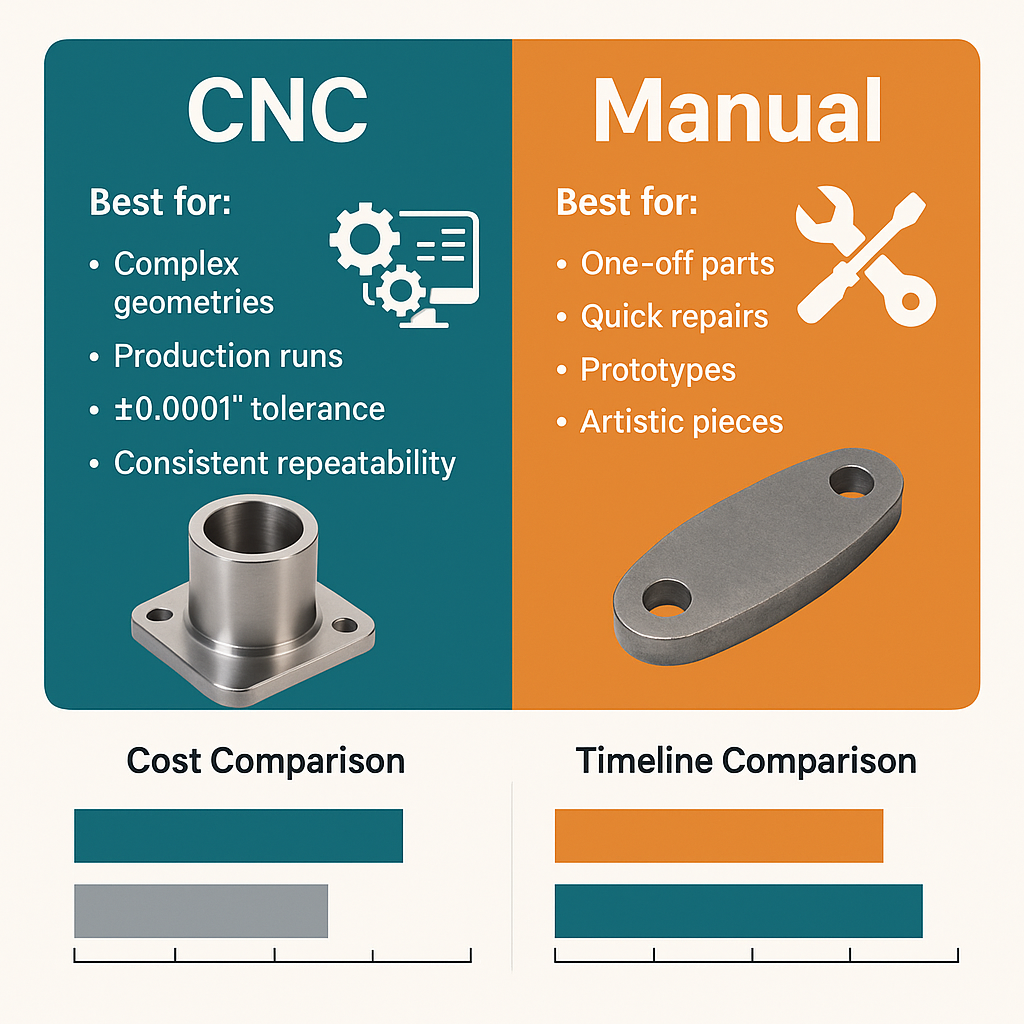

The Role of CNC Machinists: Precision and Repeatability

CNC (Computer Numerical Control) machinists are experts in automated machining. They use computer-aided manufacturing (CAM) software to program machines that execute complex cuts with incredible precision and consistency. CNC is ideal for projects with intricate geometries and for production runs where every part must be identical. A skilled CNC machinist is proficient in programming, setting up the machines, and performing in-process quality checks to ensure every component meets the blueprint specifications.

The Art of Manual Machining: Flexibility and Craftsmanship

Before CNC, all machining was done manually. Manual machinists rely on their hands-on skill, experience, and deep understanding of mechanics to operate lathes, milling machines, and grinders. While less common for high-volume production, manual machining is invaluable for one-off custom parts, repairs, and prototypes where the time and cost of CNC programming are not justified. The craftsmanship of a manual machinist allows for intuitive adjustments and creative problem-solving on the fly.

Other Specialized Machining Skills to Consider

Beyond CNC and manual operations, many other specialties exist. Some machinists focus on surface grinders to achieve exceptionally flat surfaces and tight tolerances. Others may specialize in Electrical Discharge Machining (EDM) for creating complex shapes in hard metals that are difficult to cut with a traditional tool. Look for expertise relevant to your project, whether it’s 5-axis milling for complex contours or Swiss machining for small, intricate parts.

Section 3: Essential Qualities and Skills to Evaluate in a Machinist

Beyond specialization, certain fundamental qualities separate a good machinist from a great one. These traits are universal indicators of professionalism, reliability, and a commitment to excellence.

Technical Proficiency and Equipment Acumen

A great machinist possesses a deep and intuitive understanding of their equipment. They know the capabilities and limitations of their machines, from the spindle speed of a milling center to the resolution of a lathe. This proficiency extends to automation; with 64% of small manufacturers reporting increased productivity from automation, a machinist’s ability to leverage technology is crucial. They should be able to look at a blueprint and immediately envision the sequence of operations, the necessary machines, and the best setup to produce the part efficiently.

A Sharp Eye for Detail and Unwavering Commitment to Quality

Precision machining leaves no room for error. The best machinists are meticulous, paying close attention to every detail, from interpreting tolerances on a blueprint to deburring a finished part. This commitment to quality should be ingrained in their workflow. They should be proactive about checking their work at every stage, using calibrated measurement tools to ensure every dimension is within spec before moving on to the next operation.

Problem-Solving Prowess and Adaptability

Machining rarely goes exactly as planned. A tool might wear unexpectedly, a material might behave differently than anticipated, or a workholding setup might prove unstable. An exceptional machinist doesn’t just follow instructions; they think critically and solve problems as they arise. They can diagnose issues, adapt their approach, and find creative solutions to manufacturing challenges without compromising quality or safety.

Material Knowledge and Tooling Expertise

A machinist’s knowledge must extend beyond their machines to the materials they cut and the tools they use. They understand how different metals and plastics react to heat and pressure. They know which cutting tool geometry, material, and coating are best suited for a specific job to achieve the desired surface finish and tool life. This expertise is critical for optimizing the machining process for speed, accuracy, and cost-effectiveness.

Section 4: Evaluating Potential Machinists and Their Workshops

Once you know what to look for, you need a practical method for vetting candidates. This involves a holistic assessment of their experience, communication style, and physical capabilities.

Assessing Relevant Experience and Portfolio

Ask to see a portfolio of past work. Look for projects that are similar to yours in complexity, material, and precision. A portfolio is tangible proof of their skill. In a tight labor market where finding experienced workers is a challenge, as small manufacturers may struggle to hire due to low unemployment, a strong track record is a significant differentiator. Don’t just look at the finished products; ask about the challenges they faced and how they overcame them.

Communication and Collaboration Style

Effective communication is non-negotiable. Your machinist should be responsive, clear, and willing to discuss your project in detail. They should ask clarifying questions about your blueprints and be able to explain their proposed manufacturing process in terms you can understand. Good collaboration can help mitigate the impact of skill shortages, which have led to about 20.6% of U.S. manufacturing plants operating below full capacity.

Shop Capabilities, Equipment, and Organization

The capabilities of the machine shop are as important as the skill of the machinist. Do they have the right machines for your project? Is their equipment well-maintained? An organized and clean shop is often a strong indicator of a professional and detail-oriented operation. Inquire about their measurement tools and quality control equipment to ensure they can verify the precision you require.

Certifications, Quality Standards, and Industry Affiliations

Certifications like ISO 9001 demonstrate a formal commitment to quality management systems. If your project is for a specific industry like aerospace (AS9100) or medical (ISO 13485), these certifications may be mandatory. Also, in an era of heightened digital threats, where the manufacturing sector was the most targeted industry for ransomware in 2023, ask about their data security protocols for protecting your intellectual property.

References and Reputation: What Others Say

Don’t hesitate to ask for references from past clients. Speaking with someone who has worked with the machinist before can provide invaluable insight into their reliability, quality of work, and professionalism. Online reviews and industry reputation can also offer clues, but a direct conversation with a previous customer is often the most revealing.

Section 5: The Interview Process: Essential Questions to Ask Your Potential Machinist

A structured interview allows you to systematically compare candidates and probe deeper into their expertise.

Project-Specific Inquiries

- “Looking at our blueprint, what challenges do you foresee in manufacturing this part?”

- “What is your experience working with [your specified material]?”

- “Based on the required tolerances and surface finish, what machining strategy would you propose?”

Process and Quality Assurance Questions

- “How do you ensure the quality of a part throughout the machining process?”

- “What measurement equipment would you use to verify the critical dimensions on this part?”

- “Can you walk me through your process from receiving a CAD file to shipping a finished part?”

Logistics and Communication Questions

- “What is your current shop capacity and estimated lead time for a project of this scale?”

- “How will you provide updates on the project’s progress?”

- “Who will be my primary point of contact?”

Capacity and Resource Questions

- “Do you have backup equipment in case a primary machine goes down?”

- “Are your material suppliers reliable for sourcing [your specified material]?”

- “Can you handle a potential increase in order volume if this project moves to production?”

Section 6: Local vs. Remote Machinists: Weighing Your Options

Choosing between a local and a remote machine shop involves a trade-off. A local machinist offers the advantage of in-person collaboration, easier oversight, and potentially faster shipping. You can visit the shop, inspect the equipment, and build a stronger working relationship. However, limiting your search geographically may also limit your access to specialized skills or more competitive pricing. Remote machinists and online manufacturing platforms offer a vast pool of talent and capabilities but require excellent communication and trust in their quality control processes. Your decision should be based on your project’s complexity, your need for hands-on collaboration, and logistical considerations.

Conclusion

Choosing the right machinist is an investment in the success and quality of your project. The process begins with a thorough definition of your own needs—from materials and blueprints to precision and budget. It requires you to understand the different specializations within the machining world and to evaluate candidates based on a combination of technical skill, problem-solving ability, and a demonstrable commitment to quality.

By carefully assessing a machinist’s experience, communicating your needs clearly, inspecting their shop’s capabilities, and asking targeted questions, you can mitigate risks and forge a strong partnership. This due diligence is more critical than ever, as finding truly qualified applicants remains a significant challenge for many shops. Whether you work with a local artisan or a remote CNC expert, the principles of clear communication and mutual respect are paramount. A thoughtful, methodical selection process will ensure your complex designs are transformed into high-quality, precise products that meet every specification, on time and on budget.

How to Choose a Machinist - Frequently Asked Questions

When learning how to choose a machinist, focus on five key factors: technical expertise in your required processes (CNC, manual, or specialized), experience with your specific materials, ability to meet your precision tolerances, equipment capabilities matching your project needs, and quality certifications like ISO 9001. Additionally, evaluate their communication skills, portfolio of similar work, shop organization, and references. The right machinist combines technical skill with professional reliability to deliver parts correctly the first time.

Before choosing a machinist, clearly define your project scope including whether it's a prototype or production run, exact material specifications and grades, required tolerances and surface finishes (Ra values), complete 2D blueprints and 3D CAD models, budget constraints and timeline requirements, and intended application of final parts. Document these requirements comprehensively as they form the foundation for evaluating potential machinists and ensure clear communication throughout the project.

Essential questions when choosing a machinist include: What challenges do you foresee with this blueprint? What's your experience with [specific material]? How do you ensure quality throughout the process? What measurement equipment will you use for verification? What's your current capacity and lead time? How will you provide project updates? Can you handle potential volume increases? Ask for references and examples of similar work. These questions reveal both technical competence and professional communication abilities.

The choice between CNC and manual machinists depends on your project requirements. Choose CNC machinists for complex geometries, tight tolerances (±0.0001"), production runs requiring identical parts, and projects needing CAD/CAM integration. Manual machinists excel at one-off custom parts, repairs, prototypes where programming isn't justified, and projects requiring intuitive adjustments. Many shops offer both capabilities. With 64% of manufacturers reporting increased productivity from automation, CNC is often preferred for precision and repeatability.

Shop equipment and organization are critical indicators when choosing a machinist. Well-maintained, appropriate equipment ensures capability to meet specifications. Look for calibrated measurement tools (micrometers, CMMs), machines matching your project needs, clean and organized workspace indicating professionalism, and backup equipment for reliability. A disorganized shop with outdated equipment often correlates with quality issues. The global CNC market reaching $92.4 billion by 2025 reflects the importance of modern equipment investment.

When choosing a machinist, prioritize relevant certifications: ISO 9001 for general quality management, AS9100 for aerospace projects, ISO 13485 for medical devices, and ITAR registration for defense work. These certifications demonstrate formal quality systems and industry compliance. Also verify data security protocols, as manufacturing was the most targeted sector for ransomware in 2023. Ask about their quality control processes, inspection procedures, and documentation practices to ensure consistent, traceable quality.

Choosing between local and remote machinists involves trade-offs. Local machinists offer in-person collaboration, easier oversight, faster shipping, ability to visit the shop, and stronger relationship building. Remote machinists provide access to specialized skills, competitive pricing, broader equipment capabilities, and larger capacity. Your choice depends on project complexity, need for hands-on collaboration, and logistics. For prototypes requiring iteration, local is often better. For specialized or high-volume work, remote options may offer advantages.

When learning how to choose a machinist, portfolio evaluation is crucial. Look for projects similar in complexity, material, and precision to yours, documented challenges and solutions demonstrating problem-solving, variety showing versatility, and consistent quality across different projects. Ask specific questions about their approach to past challenges. With 20.6% of manufacturing plants operating below capacity due to skill shortages, proven experience is a significant differentiator. Request references and speak directly with past clients about reliability and quality.