How CNC Machining Drives Unmatched Precision and Productivity in Modern Foundry Operations

Revolutionizing Foundry Operations with Computer Numerical Control

In today's fiercely competitive manufacturing landscape, foundries face unrelenting pressure to deliver components with unprecedented complexity, tight tolerances, and flawless consistency. Traditional casting methods, while foundational to the industry, often struggle to meet these modern demands alone. The gap between a raw casting and a finished, high-performance part requires a solution that is both powerful and precise. This is where Computer Numerical Control (CNC) machining emerges not just as a supplementary step, but as a core driver of innovation, transforming foundry operations from the ground up.

By integrating advanced automation and digital accuracy into the post-casting process, CNC machining empowers foundries to move beyond conventional limitations. It enables the production of superior-quality components, optimizes workflows, and unlocks new capabilities, ensuring foundries can meet the stringent requirements of leading industries like aerospace and automotive.

The Evolution of Foundries and the Need for Advanced Solutions

For centuries, the foundry has been the heart of industrial manufacturing, creating the foundational metal components that build our world. However, the engineering demands of the 21st century have fundamentally shifted. Industries now require parts that are lighter, stronger, and more intricate than ever before. This evolution has exposed the limitations of relying solely on the casting process, which, despite its advancements, can introduce variability in dimensions and surface finish. To remain competitive, modern foundries need a reliable method to refine raw castings into finished products that meet exacting specifications.

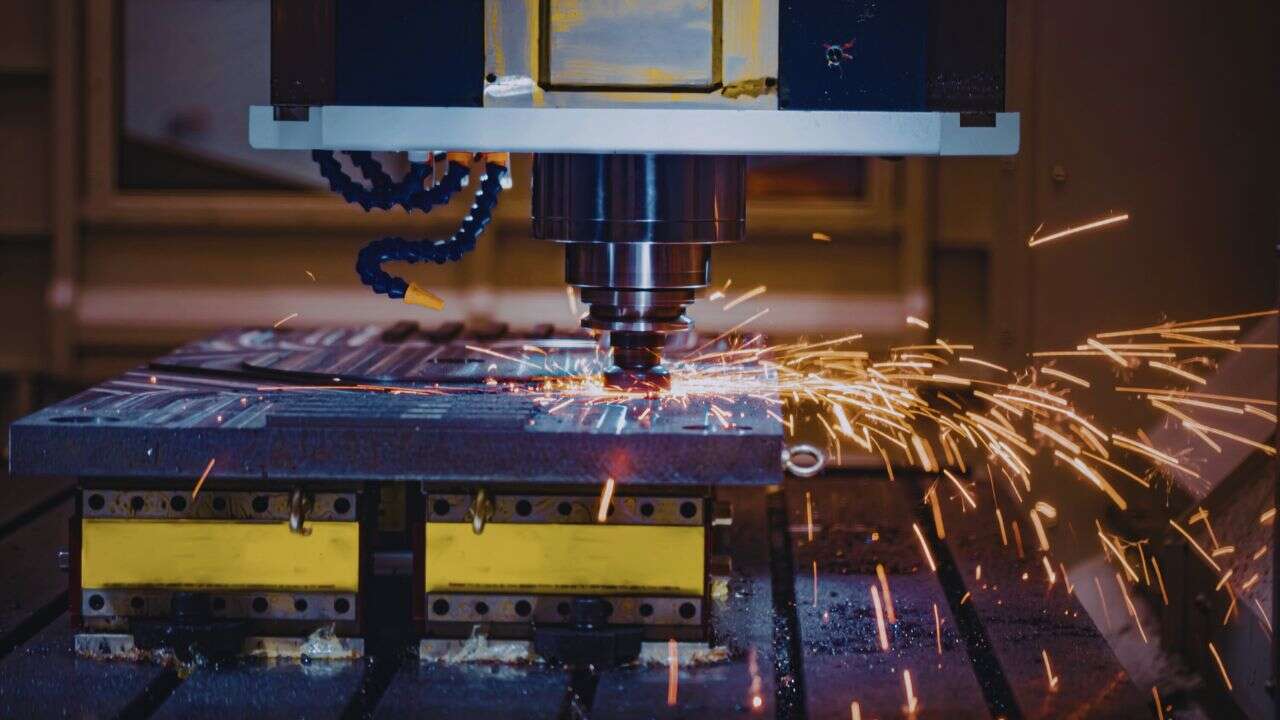

A Glimpse into CNC Machining's Transformative Power in Casting

CNC machining provides the critical link between the "near-net shape" of a casting and the final, perfect component. Imagine a raw engine block casting. While the overall form is present, the cylinder bores, mounting surfaces, and fluid channels must be finished with microscopic precision. CNC machining automates this finishing process, using computer-guided cutting tools to remove material with an accuracy that is impossible to achieve manually. This digital precision elevates the entire manufacturing process, turning rough potential into finished excellence.

Raw Casting

CNC Programming

Precision Machining

Finished Part

The Modern Foundry Landscape

Challenges and Opportunities

The contemporary foundry operates in an environment defined by high expectations and significant technical hurdles. Success is no longer measured simply by the volume of metal poured but by the quality, precision, and efficiency of the final output. This landscape presents both formidable challenges and immense opportunities for manufacturers willing to embrace technological advancement.

Meeting Demands for Tighter Tolerances and Complex Geometries

Modern engineering relies on parts fitting together perfectly. Industries like aerospace and automotive design components with geometric tolerances measured in microns. A raw casting cannot inherently meet this standard. The natural process of metal cooling and solidification introduces slight variations that, while minor, are unacceptable for high-performance applications. Furthermore, designs often include intricate internal channels, complex curved surfaces, and features that are difficult or impossible to create through casting alone. CNC machining directly addresses this challenge by refining the cast part to exact digital specifications.

⚠️ Industry Challenges

- Tolerances measured in microns

- Complex geometric requirements

- Casting variability from cooling

- Long lead times and high scrap rates

- Labor-intensive manual finishing

✅ CNC Solutions

- Sub-micron precision achievable

- Multi-axis machining capability

- Compensates for casting variations

- Automated, streamlined workflows

- Consistent, repeatable results

The Imperative for Enhanced Productivity and Reduced Waste

In a global market, efficiency is paramount. Long lead times, high scrap rates, and inefficient labor allocation can cripple a foundry's profitability. The traditional manufacturing process of manually finishing, inspecting, and reworking castings is slow, costly, and prone to human error. There is a critical need for automation to streamline these post-casting operations, increase throughput, and minimize material waste. Every rejected part represents lost time, energy, and resources—a cost modern manufacturing cannot afford.

Bridging the Gap Between Raw Casting and Finished Component Needs

A raw casting is a starting point, not a final product. It lacks the precise mating surfaces, threaded holes, and smooth finishes required for assembly and function. The fundamental challenge for any foundry is to efficiently and reliably bridge this gap. This requires a manufacturing process that is repeatable, accurate, and versatile enough to handle a wide range of part designs and material types. CNC machining provides this bridge, offering a controlled, automated solution to transform raw castings into components ready for immediate integration.

Understanding CNC Machining

A Core Technology for Foundry Advancement

To appreciate its impact on foundry operations, it is essential to understand the core principles of CNC machining. It represents a fundamental shift from manual or mechanically automated processes to a digitally driven, highly precise method of material removal.

What is Computer Numerical Control (CNC) Machining?

Computer Numerical Control (CNC) machining is a subtractive manufacturing process that uses computer-programmed instructions to control high-precision machine tools. A digital design file, typically created with CAD (Computer-Aided Design) software, is translated into a specific set of commands (G-code). These commands dictate the exact movements of the cutting tools, the spindle speed, and other variables. The CNC machine then executes this program autonomously, cutting, drilling, or milling a workpiece to create a part that perfectly matches the digital blueprint.

Automation

Minimizes manual intervention, enabling continuous 24/7 operation and reducing labor costs

Repeatability

Every part produced is virtually identical, eliminating variability and guaranteeing consistent quality

Digital Control

Unparalleled accuracy enables complex features and tolerances impossible to replicate manually

Key Principles: Automation, Repeatability, and Digital Control

The power of CNC machining lies in three key principles. First, automation minimizes the need for direct manual intervention during the machining process, allowing for continuous, 24/7 operation and reducing labor costs. Second, repeatability ensures that every part produced is virtually identical to the last, eliminating the variability inherent in manual work and guaranteeing consistent quality. Finally, digital control provides an unparalleled level of accuracy, enabling the creation of complex features and the achievement of tolerances that are physically impossible for a human operator to replicate.

Essential CNC Machines and Their Roles in Post-Casting Operations

While many types of CNC machines exist, CNC milling machines, or mills, are particularly vital for foundries. A CNC mill uses a rotating multi-point cutting tool to progressively remove material from the casting. 3-axis, 4-axis, and 5-axis CNC milling centers allow the cutting tool to approach the workpiece from multiple angles in a single setup. This capability is crucial for machining the complex geometries often found in modern castings, such as engine blocks, valve bodies, and aerospace structural components.

Unleashing Unmatched Precision

In Post-Casting Operations

The single most significant advantage CNC machining brings to a foundry is an extraordinary level of precision. This accuracy transforms the post-casting finishing stage from a potential source of error into a highly reliable and value-adding step in the manufacturing process.

Achieving Sub-Micron Geometric Accuracy

Modern CNC machines are capable of holding geometric tolerances that were inconceivable just a few decades ago. Sub-micron accuracy means that critical features of a component—such as bore diameters, surface flatness, and hole positions—can be machined to within a fraction of the width of a human hair. This level of accuracy ensures that components will fit, seal, and function exactly as the engineer intended, every single time.

📐 Sub-Micron Accuracy

Critical features machined to within a fraction of a human hair's width

✨ Superior Surface Finish

Smooth, precise surfaces for sealing, friction reduction, and aesthetics

🔁 Perfect Repeatability

Part 1,000 is identical to part 1—eliminating batch variability

📊 Digital Traceability

Every operation recorded for quality documentation and compliance

Superior Surface Finish and Its Importance

Beyond dimensional accuracy, CNC machining produces superior surface finishes. The controlled cutting action creates a smooth, uniform texture on machined surfaces. This quality is essential for sealing surfaces that must prevent fluid or gas leaks, for bearing surfaces where smooth contact reduces friction and wear, and for aesthetic requirements where a finished appearance is desired.

Repeatability and Consistency: The Backbone of Quality

Perhaps the most valuable aspect of CNC for high-volume foundry production is its repeatability. Once a program is proven, the CNC machine will replicate that exact process, producing identical parts every time. Part 1,000 will be virtually indistinguishable from part 1. This consistency is the backbone of quality, enabling foundries to guarantee that every component shipped meets the exact same high standard.

Driving Productivity and Efficiency

Optimizing Foundry Workflows

Beyond precision, CNC machining delivers a level of automation and efficiency that revolutionizes foundry workflows, leading to faster turnaround times, lower costs, and a safer working environment.

Streamlined Post-Casting Workflows and Reduced Lead Times

CNC machining can consolidate multiple finishing operations into a single, automated setup. A multi-axis CNC machine can drill, tap, mill, and bore a complex casting without needing to be manually re-fixtured. This consolidation dramatically reduces setup time, material handling, and overall cycle time. The result is a significant reduction in lead times, allowing manufacturers to respond more quickly to customer orders and accelerate the prototyping of new designs.

Reduced Lead Times

Consolidated operations in single setup accelerate production cycles

Cost Reduction

Minimized scrap, optimized toolpaths, and extended tool life lower per-part costs

Enhanced Safety

Enclosed machining protects operators while freeing skilled labor for higher-value tasks

24/7 Operation

Automated processes enable continuous production with minimal supervision

Cost Reduction Through Material Optimization and Waste Reduction

The precision of CNC machining minimizes material waste in two key ways. First, by producing parts with extreme accuracy, it virtually eliminates scrap due to dimensional errors. Second, advanced CAM (Computer-Aided Manufacturing) software can optimize the toolpaths to remove material in the most efficient way possible, reducing cutting time and extending the life of the cutting tools. This operational efficiency translates directly into lower per-part costs.

Enhancing Safety and Consistency through Automation

Traditional foundry finishing work, such as manual grinding and deburring, can expose workers to safety hazards and physically demanding tasks. CNC automation encloses the machining process, protecting operators from moving parts, sharp chips, and coolant. By automating these repetitive and often strenuous tasks, CNC machines not only improve workplace safety but also free up skilled labor to focus on higher-value activities like quality control, programming, and process improvement.

Addressing Foundry-Specific Challenges

With CNC Machining

Foundries deal with unique material and geometric challenges that CNC machining is exceptionally well-suited to solve. It provides the flexibility and power needed to work with the realities of cast metal components.

Machining Diverse Foundry Materials with Ease

Foundries work with a vast array of metals, from cast iron and aluminum alloys to stainless steels and high-temperature superalloys. Each material has unique machining characteristics. CNC machines, equipped with the correct cutting tools, speeds, and feeds, can be programmed to effectively machine any of these materials. This versatility allows foundries to serve a broad customer base without needing entirely different sets of finishing equipment.

From cast iron and aluminum alloys to stainless steels and high-temperature superalloys—CNC machines can be programmed to effectively process any foundry material, serving diverse customer requirements with a single equipment platform.

Creating Intricate and Complex Cast Geometries

CNC machining excels where manual methods fail. It is the ideal technology for creating the intricate features common in modern castings, such as thin walls, deep pockets, and complex curved surfaces. 5-axis CNC milling, in particular, can machine complex components like impellers and turbine blades in a single clamping, ensuring perfect relationships between all features and enabling designs that were previously considered unmanufacturable.

Compensating for Casting Imperfections and Variability

No casting process is perfect; minor variations in shrinkage, parting lines, or surface texture are inherent. CNC machining effectively erases these imperfections. By referencing key datums on the cast part, the CNC program can accurately machine all critical features in relation to one another, regardless of slight variations in the raw casting. This ability to impose perfect geometry onto an imperfect starting shape is a core benefit for foundries.

Advanced CNC Technologies

Elevating Foundry Capabilities

The evolution of CNC technology continues to push the boundaries of what is possible in manufacturing. Integrating these advancements allows foundries to further enhance their precision, speed, and overall efficiency.

CAD/CAM Integration for Seamless Design-to-Production Workflow

Modern CNC operations are built on a seamless digital thread. Designs created in CAD software are directly imported into CAM software, where programmers generate and simulate the machine toolpaths. This tight integration minimizes the risk of data translation errors and allows for rapid design updates. For foundries, this means a faster transition from customer design to finished part, facilitating quicker prototyping and production runs.

🔗 CAD/CAM Integration

Seamless digital workflow from design to production with minimal translation errors

🏎️ High-Speed Machining

Faster spindle speeds and optimized toolpaths improve cycle time and surface finish

🔄 Multi-Axis Centers

5-axis capability produces complex parts with fewer setups and higher accuracy

🛠️ Advanced Tooling

Specialized carbide tools with coatings optimize performance on cast materials

High-Speed CNC Milling and Multi-Axis CNC Machining Centers

Modern CNC machines are faster and more capable than ever. High-speed machining techniques use faster spindle speeds and optimized toolpaths to remove material more quickly while improving surface finish. Simultaneously, the proliferation of 5-axis CNC machining centers provides the ultimate flexibility, enabling the production of highly complex parts with fewer setups, which improves accuracy and reduces cycle time.

The Importance of Cutting Tools and Machine Tool Selection for Castings

The success of any CNC operation depends on using the right tools for the job. Machining cast materials, which can have a tough outer "skin" and may contain abrasive particles, requires durable cutting tools made from materials like carbide with specialized coatings. Selecting the right geometry and type of cutting tool is critical for achieving optimal performance, surface finish, and tool life, directly impacting the cost-effectiveness of the manufacturing process.

Real-World Impact

Industries Transformed by CNC-Equipped Foundries

The combination of casting and CNC machining is the driving force behind innovation in some of the world's most demanding industries. The ability of foundries to deliver precisely finished castings is critical to their success.

Aerospace and Defense: Precision Components for Turbine Blades and Structural Parts

In the aerospace industry, there is no room for error. Components like turbine blades, engine housings, and structural airframe parts are often cast from advanced alloys to save weight and withstand extreme conditions. CNC machining is the only way to finish these castings to the required sub-micron tolerances and complex aerodynamic profiles. The safety and performance of modern aircraft depend on the precision that this manufacturing partnership provides.

The integration of CNC machining is no longer a luxury for foundries; it is a strategic necessity for survival and growth in the modern manufacturing era. By bridging the critical gap between a raw casting and a finished, high-precision component, CNC technology directly addresses the industry's most pressing challenges.

It delivers the unparalleled accuracy required by sectors like aerospace and automotive, drives the productivity needed to remain profitable, and provides the flexibility to tackle complex designs and diverse materials.

For foundry leaders, embracing CNC machining is an investment in quality, efficiency, and capability. It streamlines workflows, reduces waste, enhances safety, and ultimately elevates the value a foundry can offer its customers. By adopting a digitally driven manufacturing process, foundries can not only meet the demands of today but also position themselves as innovative partners capable of bringing the most ambitious engineering designs to life. The path forward is clear: the fusion of ancient casting techniques with modern CNC precision is the formula for unmatched performance and enduring success.

🎯 Key Takeaways

- CNC machining bridges the gap between raw castings and finished precision components

- Sub-micron accuracy and superior surface finishes meet the most demanding specifications

- Automation enables 24/7 operation with consistent, repeatable quality

- Streamlined workflows reduce lead times and per-part costs

- Multi-axis capability handles complex geometries in fewer setups

- Versatile processing of diverse foundry materials from one platform

- Enhanced workplace safety through enclosed, automated operations

Ready to Elevate Your Casting Projects?

Partner with experts in foundry operations and precision CNC machining. Contact Dews Foundry to discover how our integrated capabilities deliver unmatched quality and efficiency for your components.

Contact Dews Foundry