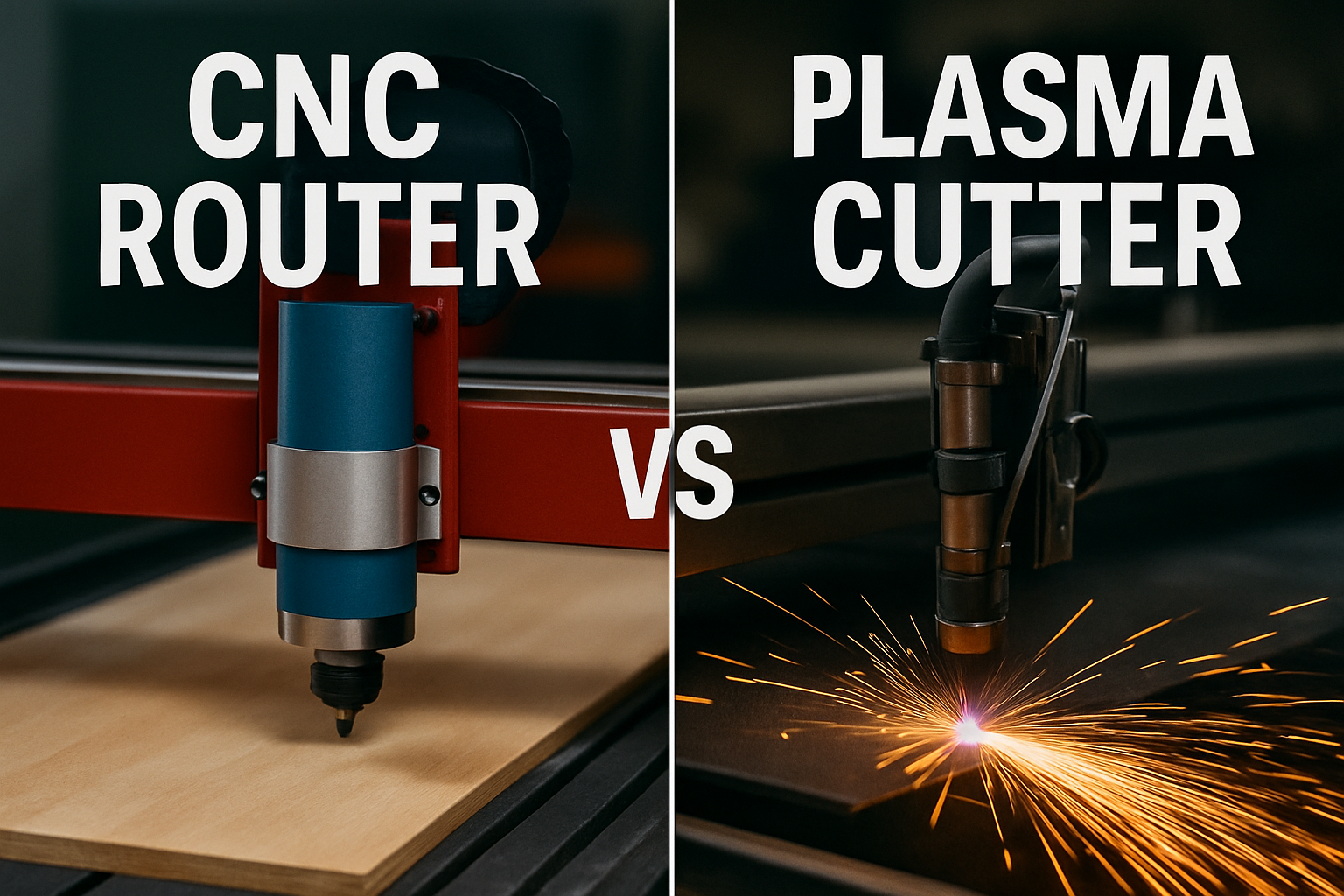

In the world of digital fabrication, choosing the right cutting tool can make or break your production efficiency. Two of the most widely used systems—CNC routers and CNC plasma cutters—often serve overlapping yet distinct functions. But if you’re comparing a CNC router vs plasma cutter, it’s critical to understand how each machine works, what materials they handle best, and which applications suit their strengths.

Whether you’re fabricating furniture, signage, industrial components, or structural steel, this guide breaks down the technical and practical differences to help you make the right choice.

Before weighing the differences between routers and plasma cutters, it’s helpful to have a solid grasp of the underlying technology. If you need a refresher, check out our guide on what a CNC machine is — it covers how CNC systems work and why they’re foundational to both tools discussed here.

What Is a CNC Router?

A CNC router is a computer-controlled cutting machine typically used for soft materials like wood, plastic, foam, and non-ferrous metals (e.g., aluminum). It uses a high-speed rotating bit to carve, shape, or drill material based on pre-programmed instructions (G-code).

Key Characteristics:

Uses mechanical cutting (rotating bit)

Ideal for precise, detailed engraving or carving

Typically operates at higher RPMs and lower feed rates

What Is a CNC Plasma Cutter?

A CNC plasma cutter uses a high-velocity jet of ionized gas (plasma) to melt and blow away metal. It’s built to slice through electrically conductive materials with speed and power.

Key Characteristics:

Uses heat (plasma arc) to cut

Designed for thick metals like steel and stainless steel

High-speed, lower-precision compared to routers

To explore more about the strengths of CNC plasma cutting, Dews Foundry offers precision cutting solutions tailored to industrial applications.

CNC Router vs Plasma Cutter: Side-by-Side Comparison

| Feature | CNC Router | CNC Plasma Cutter |

|---|---|---|

| Cutting Method | Mechanical (rotating bit) | Thermal (ionized gas arc) |

| Materials Best Suited For | Wood, plastic, foam, aluminum | Mild steel, stainless steel, aluminum |

| Cut Quality | Clean, detailed edges | Slightly rougher edges, dross possible |

| Thickness Capability | Up to 2 inches (varies by material) | Up to 2 inches or more for steel |

| Speed | Moderate | Very fast (especially on thicker metals) |

| Operating Environment | Cleaner (less smoke and noise) | Requires ventilation and fume extraction |

| Cost | Lower initial cost | Higher operating cost due to consumables |

Use Cases: Which Should You Choose?

Choose a CNC Router if you:

Work primarily with wood, acrylics, or plastics

Need engraving or detailed contour cuts

Are prototyping for packaging, signage, or furniture

Want low-noise, clean cutting in an office or light-shop environment

Choose a CNC Plasma Cutter if you:

Need to cut thick sheet metal or steel plates

Prioritize speed over fine detail

Work in metal fabrication, automotive, or structural steel industries

Can accommodate ventilation and safety requirements

Cost Considerations

CNC Routers typically have lower setup and maintenance costs. Bit replacement is infrequent, and energy use is minimal.

CNC Plasma Cutters come with higher operational costs due to consumables like electrodes, nozzles, and the need for fume extraction systems.

However, plasma cutters often pay for themselves faster in high-volume metalworking environments thanks to their cutting speed.

Precision vs. Power

This is the core trade-off:

Routers excel in precision for fine-detail and edge-finish quality.

Plasma cutters dominate in power and speed for thick, conductive materials.

Choosing between the two means evaluating your material types, design complexity, and output requirements.

Mixed-Fabrication Shop & CNC Cutter Efficiency

A fabrication company handling both signage and metal framing split their workflow:

CNC Router for high-detail acrylic signs and prototype enclosures.

Plasma Cutter for fast-turnaround steel brackets and frames.

By aligning machine capability with task, they increased output by 45% without sacrificing quality.

A study in The International Journal of Advanced Manufacturing Technology found that material choice and part complexity significantly impact CNC machine selection. CNC plasma cutting offers up to 70% faster throughput for mild steel when compared to routers, while routers provided superior surface quality for polymeric and wooden substrates (source).

Know the Difference, Maximize the Output

The difference between a CNC router and plasma cutter comes down to your core business needs. Routers are ideal for lightweight, detailed work. Plasma cutters are built for speed and heavy-duty metal fabrication.

Investing in the right system means more than just cutting parts—it’s about cutting costs, downtime, and inefficiencies. Choose wisely, and your shop runs smarter, faster, and more profitably.