Introduction: The Unyielding Demand for Precision and Performance

In today’s most demanding industries, from medical technology to aerospace, the push for innovation is relentless. This drive manifests in the design of increasingly complex, high-performance industrial components that must operate flawlessly under extreme conditions. Standard manufacturing methods often fall short, unable to produce the intricate geometries, meet the ultra-tight tolerances, or handle the advanced materials these applications require. This is where custom machining solutions become indispensable, offering a tailored approach to transform complex designs into tangible, reliable parts. The global market for special and custom machinery, estimated at USD 21.1 billion in 2024, underscores the critical and growing need for these specialized services.

The Evolving Landscape of Industrial Innovation

Innovation is no longer just about new ideas; it’s about the physical realization of those ideas. Components are becoming smaller, stronger, and more functionally integrated. Designs feature complex curves, internal channels, and thin-walled structures that defy traditional production. This evolution necessitates a manufacturing partner who can move beyond basic production and engage in a deep, collaborative process to solve engineering challenges before they arise. The success of a final product often hinges on the quality and precision of its individual components, making the choice of a machining service provider a strategic decision.

The Critical Role of Custom Machining in Modern Manufacturing

Custom machining is the art and science of creating unique components to exact specifications, often for low-volume, high-stakes applications. Unlike mass production, it focuses on precision, adaptability, and problem-solving. This approach is essential for prototyping new designs, producing highly specialized parts for critical systems, and manufacturing components from exotic or difficult-to-machine materials. By leveraging advanced technology and deep machining expertise, custom machining services bridge the gap between ambitious engineering design and functional, high-performance reality.

Decoding Complexity: The Core Challenges in High-Performance Component Manufacturing

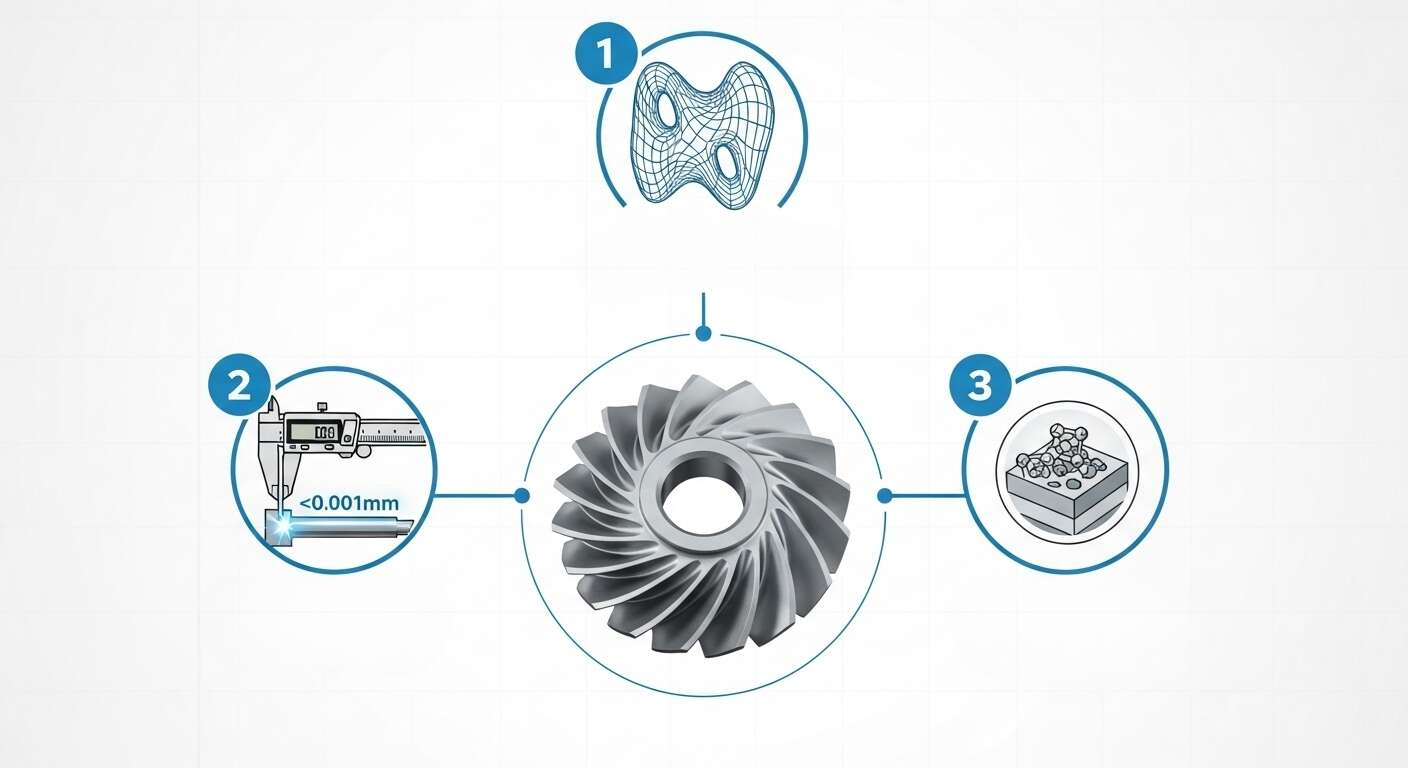

The trio of interconnected challenges—complex geometries, tight tolerances, and advanced materials—that custom machining must overcome.

The trio of interconnected challenges—complex geometries, tight tolerances, and advanced materials—that custom machining must overcome.

Mastering the production of high-performance components means directly confronting a trio of interconnected challenges. Each requires a unique combination of technology, strategy, and expertise to overcome. Successfully navigating these hurdles is what separates a standard machine shop from a true custom machining solutions partner.

Intricate Geometries and Unconventional Designs

Modern design software allows engineers to create components with unparalleled geometric freedom, optimizing them for performance, weight, and function. However, these designs—featuring organic curves, deep pockets, and non-uniform surfaces—present significant manufacturing hurdles. The primary challenge lies in physically creating these shapes without compromising structural integrity or surface finish. This requires advanced machinery and sophisticated programming to control the cutting tool’s movement with absolute precision across multiple axes simultaneously. A single miscalculation in the tool path can render a complex and expensive part useless.

Ultra-Tight Tolerances and Micro-Level Accuracy

For high-performance components, especially in the medical or aerospace sectors, precision is non-negotiable. Tolerances, or the permissible limits of variation in a physical dimension, are often measured in ten-thousandths of an inch. Achieving and consistently holding these ultra-tight tolerances across an entire production run is a formidable challenge. It is influenced by numerous factors, including machine rigidity, tool wear, material stability, and even ambient temperature fluctuations in the manufacturing facility. This level of accuracy demands not only state-of-the-art CNC machines but also a meticulously controlled process and rigorous quality assurance protocols.

Conquering the Toughest Materials

The performance of a component is intrinsically linked to the materials from which it is made. Industries are increasingly relying on advanced alloys like Inconel, titanium, and specialized stainless steels for their superior strength-to-weight ratios, corrosion resistance, and ability to withstand extreme temperatures. However, these same properties make them notoriously difficult to machine. They can be abrasive, generate excessive heat during cutting, and resist material removal, leading to rapid tool wear and potential part deformation. Overcoming these challenges requires profound machining expertise, including specialized cutting tools, optimized cutting parameters (speeds and feeds), and advanced cooling strategies tailored to the specific material’s behavior.

Our Strategic Blueprint: Mastering Complexity Through Advanced Solutions

Our approach to custom machining is built on a strategic framework designed to proactively manage and master complexity. By integrating advanced technology with deep engineering knowledge, we transform manufacturing challenges into high-performance components. This blueprint ensures precision, efficiency, and reliability from concept to completion.

Proactive Design for Manufacturability (DFM)

The most effective way to master complexity is to address it at the earliest stage: the design phase. Our process begins with a collaborative Design for Manufacturability (DFM) analysis. We partner with our clients to review their designs, identifying potential manufacturing challenges and suggesting modifications that can improve quality, reduce cycle times, and lower costs—all without compromising the component’s intended function. This proactive dialogue ensures the final design is not only innovative but also optimized for precise and efficient production using our advanced CNC machining capabilities.

State-of-the-Art CNC Machining Technologies for Unmatched Precision

At the core of our operations is a suite of advanced CNC (Computer Numerical Control) machines. The global CNC machine market is projected to expand significantly, reaching USD 194.3 billion by 2034, a testament to its foundational role in modern manufacturing. Our capabilities include:

- CNC Milling: Utilizing high-speed milling machines, we execute complex cutting operations to shape parts from solid blocks of material. Our CNC Milling services are perfect for creating intricate features like pockets, slots, and contours.

- CNC Turning: Our CNC lathes produce high-precision rotational components with exceptional accuracy and surface finishes. This process is ideal for shafts, flanges, and other cylindrical parts.

- Multi-Axis Machining: Our 5-axis CNC machines are transformative, allowing the cutting tool to approach a workpiece from five different directions simultaneously. This capability enables the creation of highly complex geometries in a single setup, reducing handling, improving accuracy, and increasing efficiency. The adoption of such advanced technologies has already enabled a 35% rise in complex part production across the industry.

- Wire EDM: For features that are impossible to create with traditional cutting tools, we employ Wire Electrical Discharge Machining (EDM). This process uses a thin, electrically charged wire to cut through hardened materials with extreme precision, creating sharp internal corners and intricate details.

Engineering Advanced Tooling and Workholding Strategies

A CNC machine is only as good as the tooling that cuts the material and the fixture that holds it. For complex components, standard workholding solutions are often inadequate. Our engineers design and fabricate custom fixtures that secure the workpiece rigidly and precisely, preventing vibration and ensuring dimensional stability throughout the machining process. We also select application-specific cutting tools, considering factors like material, geometry, and required surface finish to optimize performance and tool life.

Process Optimization and Expert Machining Engineering

Technology alone does not guarantee success. True mastery comes from the human element—our team’s deep machining expertise. Our engineers and programmers utilize advanced CAM (Computer-Aided Manufacturing) software to develop the optimal tool path for every operation. This involves strategically planning each cut to maximize material removal rates while minimizing tool pressure and heat generation. This meticulous process optimization is crucial for maintaining tight tolerances, achieving superior surface finishes, and unlocking the full potential of both our CNC machines and the advanced materials we work with.

The Pillars of Trust: Quality, Reliability, and Collaborative Partnership

Delivering high-performance components that operate in critical applications requires more than just technical capability; it demands an unwavering commitment to quality and a foundation of trust. Our entire process is built on a framework of rigorous quality control, comprehensive documentation, and a truly collaborative partnership with our clients.

Uncompromising Quality Assurance and Control Systems

Quality is not an afterthought; it is embedded in every step of our manufacturing process. Our quality management system is certified to ISO 9001:2015 standards, a formal recognition of our commitment to consistency, continuous improvement, and customer satisfaction. We utilize advanced metrology equipment, including Coordinate Measuring Machines (CMMs), to perform in-process inspections and final verification of all precision components. This ensures that every part we deliver conforms exactly to the specified dimensions and tolerances, providing our clients with the absolute confidence that their components will perform as designed.

Robust Documentation and Traceability for Critical Components

In industries like medical and aerospace, traceability is paramount. We provide comprehensive documentation packages that offer full traceability of materials, processes, and inspection results. From material certifications at the start of a project to final inspection reports upon completion, we maintain a complete and transparent record for every component. This robust documentation ensures accountability and provides the necessary data for regulatory compliance and quality audits, giving our clients peace of mind.

Strategic Customer Collaboration and Project Management

We view ourselves as an extension of our clients’ engineering teams. Our approach is rooted in open communication and strategic collaboration. From the initial DFM review to final delivery, we provide regular updates and maintain a responsive dialogue to ensure projects stay on track and meet all objectives. Our dedicated project managers serve as a single point of contact, streamlining communication and ensuring that every detail is managed with precision. This partnership model allows us to better understand our clients’ needs, anticipate challenges, and deliver custom machining solutions that truly align with their goals.

Impact Across Industries: Where Custom Machining Delivers Excellence

The principles of mastering complexity through precision machining are not confined to a single sector. They are universally applicable, enabling innovation and ensuring reliability across a diverse range of industries where performance is critical.

Enabling Innovation in Critical Sectors

Our CNC Machining Services provide the foundational components for breakthroughs in several key fields:

- Medical: We produce highly complex and precise components for surgical instruments, diagnostic equipment, and medical implants. In the medical field, there is zero tolerance for error, and our ability to work with biocompatible materials to micro-level accuracies is essential.

- Aerospace & Defense: From structural airframe components to intricate parts for guidance systems, we deliver components that meet stringent requirements for strength, light weight, and performance under extreme conditions.

- Technology & Electronics: We manufacture custom housings, heat sinks, and other precision components for the semiconductor and electronics industries, supporting the development of next-generation technologies.

- Energy: Our machining expertise is crucial for producing durable components for exploration equipment and power generation systems that must withstand harsh environments and high operational stresses.

Diverse High-Performance Components We Produce

Our capabilities allow us to produce a vast array of complex parts. This includes multi-faceted manifolds with intricate internal passageways, lightweight yet strong structural brackets, high-tolerance housings for sensitive electronics, and precision shafts and actuators for automated systems. Each of these components presents a unique set of challenges that our strategic approach is designed to solve.

From Prototype to Production: Scalable Solutions for Complexity

Our value extends across the entire product lifecycle. We support R&D teams with rapid prototyping, allowing them to iterate on designs quickly and effectively. As a design matures, we seamlessly transition to producing low-to-medium volume production runs. Our scalable CNC machining processes ensure that the same level of precision and quality demonstrated in the prototype is maintained across every part, providing a reliable and efficient path from initial concept to market-ready product.

Conclusion: Your Partner in Mastering Manufacturing Complexity

The relentless demand for higher performance and greater innovation has fundamentally reshaped industrial manufacturing. Complex designs, advanced materials, and exacting tolerances are no longer exceptions but the new standard for critical components. Meeting this standard requires a departure from conventional production and a deep commitment to mastering complexity through specialized knowledge and technology.

Reaffirming Our Commitment to Precision and Performance

Our entire operational philosophy is centered on transforming intricate engineering challenges into flawless, high-performance components. By integrating proactive design collaboration, state-of-the-art multi-axis CNC machining, and an unwavering quality framework certified to ISO 9001:2015, we provide more than just Machining Services—we deliver confidence and reliability. This holistic approach ensures that every component we produce is ready for its critical role.

The Strategic Advantage of Partnering for Custom Machining Solutions

Choosing the right manufacturing partner is a strategic decision that directly impacts innovation, quality, and time-to-market. By partnering with a dedicated custom machining expert, you gain access to a team committed to solving your most difficult manufacturing problems. As the custom machining solutions market continues to grow, driven by factors like increasing industrial automation, aligning with a capable partner becomes a significant competitive advantage. We invite you to leverage our expertise to bring your most ambitious designs to life, confident that the complexity will be mastered with precision and purpose.