HISTORY

Dews Foundry’s History

How it was founded:

Carrington Luther (C.L.) Dews, was born in Virginia, into a family of tobacco farmers, but decided he would take a different route of occupation. He left home at an early age after receiving a job from Lynchburg Pipe and Foundry Co. He eventually moved to Birmingham, AL to work with Hardy – Tines Foundry. C.L. came to Mississippi from Birmingham in the mid 1930s. C.L. came to Mississippi to run another foundry on Mobile Street. When C.L. began to work for that foundry, they were working on the construction of a military base south of Hattiesburg called Camp Shelby; it was there that they made a name for themselves in the South.

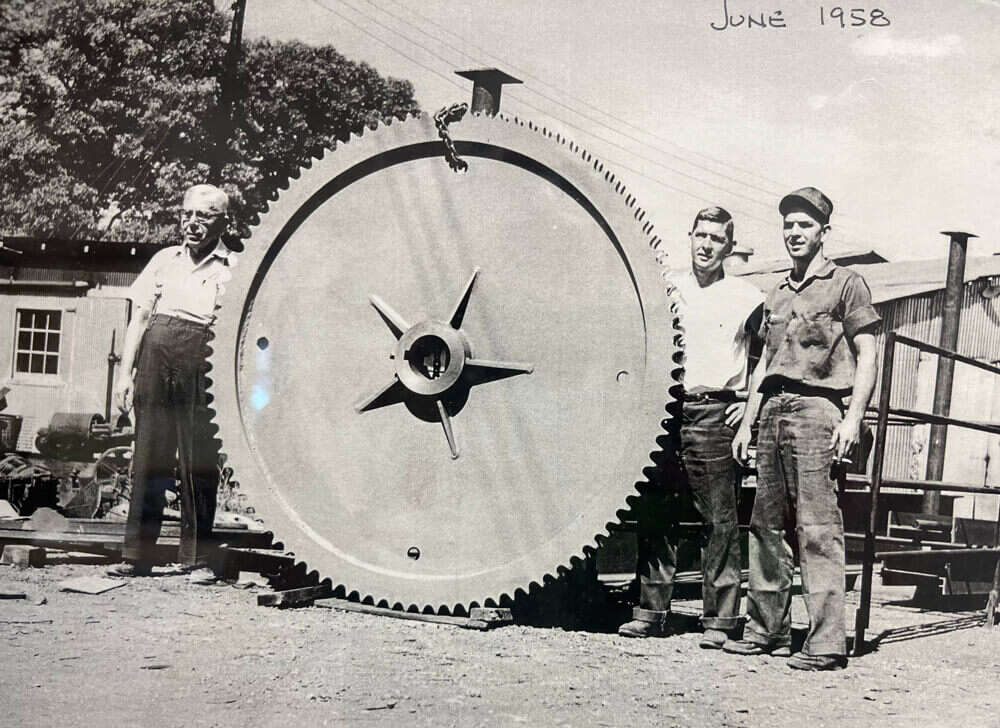

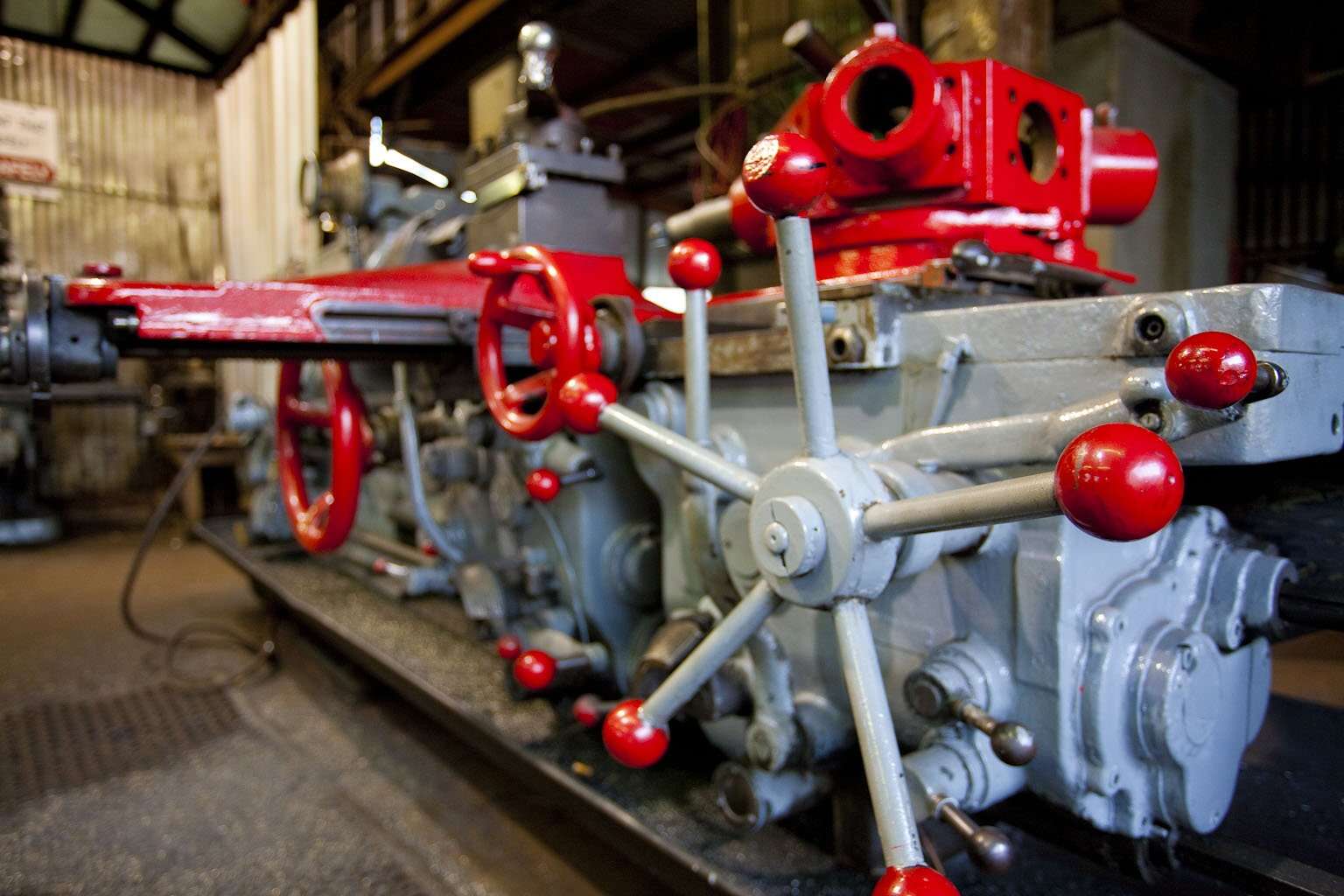

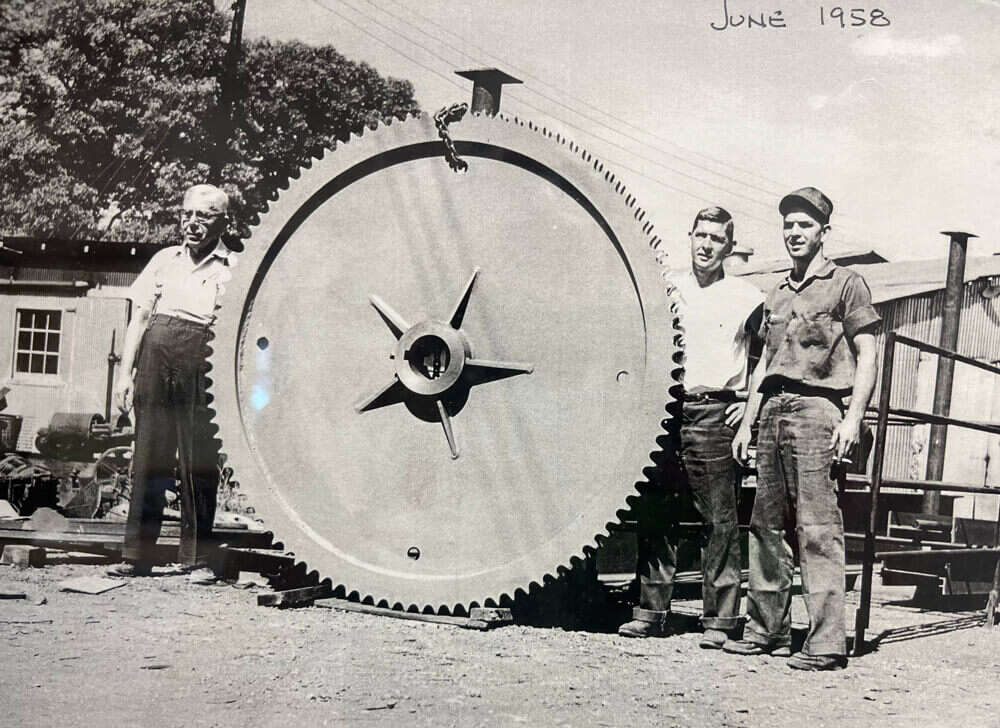

The foundry was once called Hattiesburg Foundry and also Enterprise Foundry. At this time, Hattiesburg was a huge logging, timber and sawmill town and the local foundries were used to supply the mills. The owner of that foundry was a gentleman by the name of Mr. A.B. Maynard and in 1939 C.L. leased the foundry from Mr. Maynard and subsequently purchased the foundry in 1941. C.L. had two sons and two daughters their names were Evelyn Lee, C.L. Jr., Alvin Burns, and Gloria Nell. During World War II, C.L. Jr. and Burns enlisted in the navy and in 1945 after their time in the service, they came back to the foundry and during Christmas of that year the foundry burned down. After the fire, in 1946, the foundry moved locations, to where Dews Foundry is currently located. When C.L. retired from the foundry he decided to go back to his old roots and pursue the farm industry again, he had a good crew working for him, including both of his sons and one daughter. The company started out as a foundry, added a machine shop, and in the 1950’s added a steel fabrication department. Mr. Carrington Luther Dews Sr. passed away in September 1973 but he left a legacy that still lives on through the hard working generations that have come after.

Steel Fabrication History:

The steel shop started out building general fabrications and when the Eisenhower Interstate Program grew in the 1960’s they began receiving a substantial amount of work due to highway related products. These products included bridge bearings, embedded items for bridges, guard rail brackets, etc. This work took the steel fabrication shop to a whole new level within the business so much so that it became the primary focus of the business.

Foundry History:

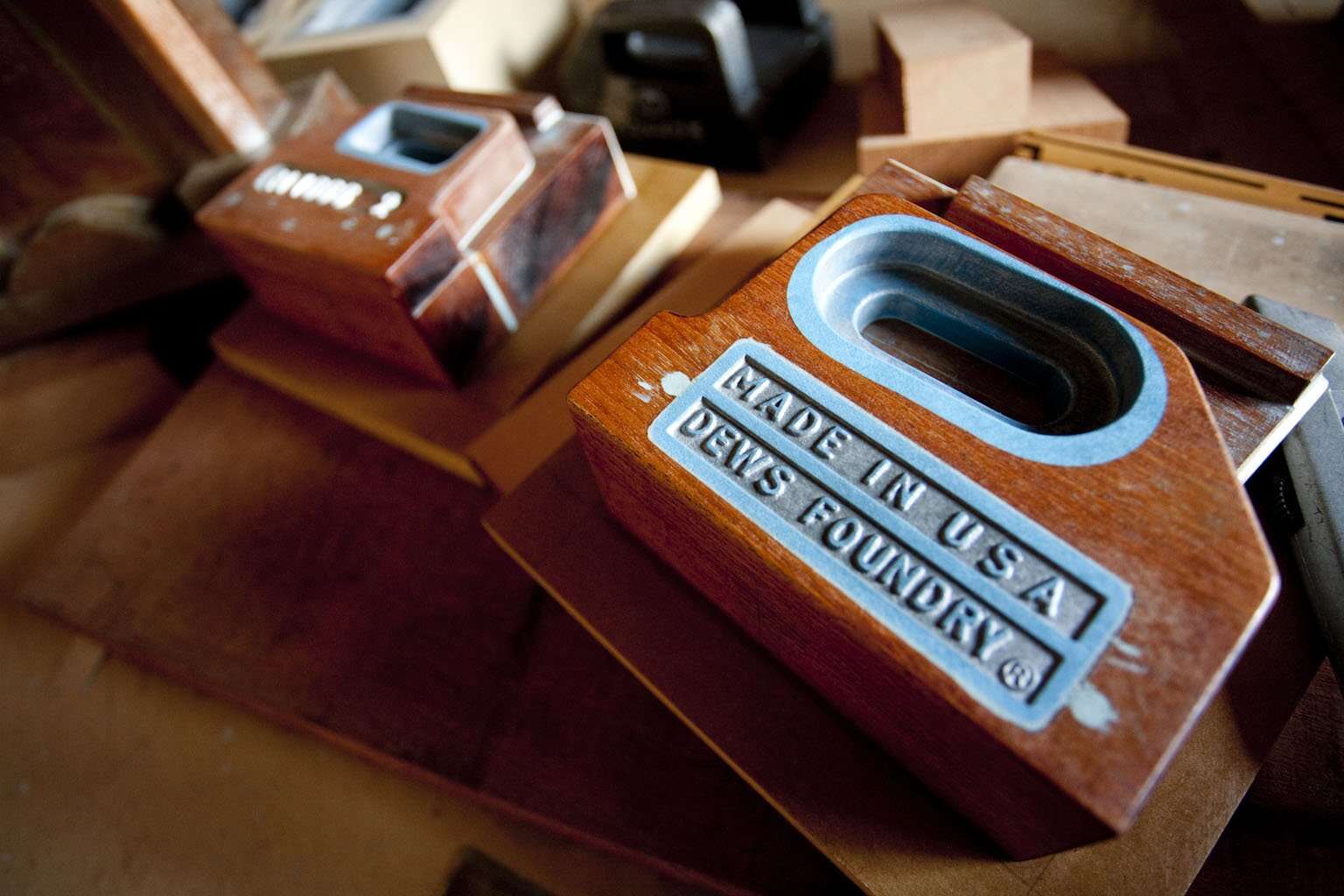

In the early days of the foundry the primary method of melting iron was using cupola melting. The foundry did their molding in what is called green sand molding. However, in the 1970’s the EPA began to enforce strict regulations on foundries. At that time, Dews switched to electric induction melting, which replaced the old smoke stacks. The electric induction method is still the method we use today. The green sand molding was also a very difficult art, it took enormous amounts of time, someone leaning over almost all day, and a lot of wasted effort. To get the proper mold was nearly impossible without a strenuous process. As employees who knew the trade began to grow older they weren’t able to do the molds anymore and new employees weren’t interested in learning the trade. During this stage, the foundry switched to a no bake system for molding.

This was both a good decision and difficult decision for the foundry. Switching to the no bake system took the art out of the molding, but it was a more precise, consistent, less strenuous system for molding. The system took very little time and the workers were using a roller bed instead of having to bend over constantly. The furnace was electric, which allowed you to adjust the metal and run your chemistry while it was still in the furnace. It gave the employees many advantages over the cupola method. From a quality stand point it was a good decision and simply made more sense.

As the 1970’s rolled along the foundry was in the process of helping out and receiving business from a company in Jackson. After that business was sold, we acquired business from Fairbanks Scales in Meridian. They had a need for cast iron scales at the time to supply to the cattle industry, and we were able to supply the castings for their scales. In the mid to late 80’s we noticed a trend of more castings being imported from India and China especially standard cast iron castings. It was during this time that we started to evaluate and discover other markets that might be advantageous for us to enter. With the municipal casting market trending to imported castings we made the decision to partner with a company out of Baton Rouge that made dredge pump parts. We began working for them by making dredge pump parts but after several years, they decided to sell the company.

Dews Foundry purchased that company, hired some of their foremen and purchased some of their equipment and began to make their own dredge pumps. Due to our entry into that market it led us to where we are today in the mining and recycling casting business. That decision led to an explosion in new business opportunities within the foundry, so much so that a decision was made to expand and build a new foundry which opened in 1995.

Now the company’s revenues are split evenly across the fabrication, machine shop, and foundry divisions. Presently the foundry division is one of the industry leaders in supplying OEM and aftermarket parts in minerals processing, mining, and crushing equipment.

At the conclusion of WWII, his two sons C. L. Jr. and Burns returned from naval service and joined in the business. The original foundry was destroyed by fire in the winter of 1945 and a new building was constructed at our current location on Edwards Street. One of C. L.’s two daughters, Evelyn Dews Boone, joined the business as the bookkeeper in 1955. From these founders, Dews Foundry currently is managed by five members of the third generation and five members of the fourth generation.

The product line for the foundry has continually evolved over our eight decades of existence. The original products of gray iron for the lumber industry have primarily been replaced by high chrome irons for the mining industry. The molding process has changed from green sand to chemically bonded sands. The melting process of gas fired cupola has been replaced by electric induction melting.

Steel fabrication was added in the mid 1950’s. The original products were for commercial buildings to include beams, columns and bar joist. The 1960’s saw the Eisenhower Interstate program and the steel fabrications moved toward highway construction fabrications such as bridge bearings. The machine shop was able to compliment both the foundry products and the highway fabrications.

Associations and Certifications

Community Involvement

University of Southern Mississippi Circle of Champions.

Vulcan Materials & Cure Finders benefiting Cystic Fibrosis

Vulcan Materials – Southwest Division benefiting -University of Texas

Health Science Center for Cancer Therapy & Research

Martin Marietta Materials benefiting American-

Diabetes Association

United Way

Area Development Partnership (ADP)

American Heart Association

Palmer Home for Children